Popular in your industry

Related Searches:

Top categories

About windscreen molding

Introduction to Windscreen Molding

Windscreen molding is an essential component in the automotive industry, serving as a seal between the glass and the vehicle body. This product category encompasses a variety of materials and designs, each tailored to provide a secure fit and protection against environmental elements. Windscreen molding ensures a finished look and contributes to the aerodynamic profile of vehicles.

Types and Applications

The versatility of windscreen molding allows for its use in multiple applications. From standard passenger vehicles to heavy-duty trucks, each type of molding is designed to meet specific requirements. The product range includes everything from pre-formed gaskets to customizable strips, suitable for use in not only automotive but also in industrial settings where sealing and insulation are necessary.

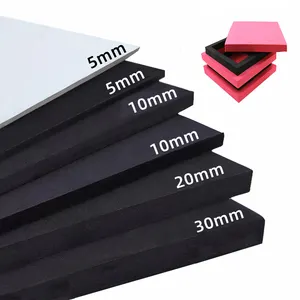

Material Composition and Features

Materials used in windscreen molding are selected for their durability and resistance to various elements. Commonly, these moldings are made from rubber or silicone, materials known for their flexibility and resilience. The inherent properties of these materials ensure that the moldings remain intact and functional in diverse weather conditions, resisting water and oil exposure effectively.

Advantages of Windscreen Molding

The advantages of using windscreen molding are manifold. Its elasticity allows for a snug fit, reducing noise and preventing leaks. The tensile strength of the materials ensures that the molding will not tear easily, even when stretched, making it a reliable choice for both automotive manufacturers and aftermarket services. Additionally, the adaptability of the material means it can be reshaped and customized without losing its integrity.

Design and Customization

Windscreen molding is not only functional but can also be aesthetically pleasing. Available in various colors, it can be designed to complement the vehicle's appearance. The design process also allows for the creation of moldings that can be stretched and fitted into complex shapes, essential for modern vehicle designs that feature curved or uniquely shaped glass.

Industrial and Military Use

Beyond the automotive industry, windscreen molding finds its place in more demanding environments, including aerospace and military applications. The robustness of the material and its ability to withstand extreme conditions make it suitable for use in equipment that requires high-performance sealing solutions.