Introduction to Vertical Shoe Sole Machines

Vertical shoe sole machines are integral components in the footwear manufacturing industry, designed to streamline the production of shoe soles. These machines vary in functionality, from automated high-capacity models to precision-driven manual devices, catering to diverse manufacturing needs.

Types and Applications

The versatility of vertical shoe sole machines is evident in their various types, each serving a specific function in shoe sole production. From intricate sole cutting to detailed embossing, these machines facilitate multiple stages of the manufacturing process. Their applications span from creating basic footwear components to adding sophisticated design elements to the soles.

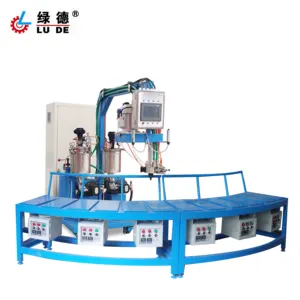

Features and Technical Specifications

Vertical shoe sole machines boast features that enhance efficiency and precision. Equipped with advanced control systems, they offer consistent performance and adaptability to different materials and designs. Technical specifications may include pressure ratings, motor power, and machine dimensions, which are crucial for buyers to consider based on their production requirements.

Materials and Construction

The construction of vertical shoe sole machines involves robust materials that ensure durability and reliability. Manufacturers utilize metals and composites that withstand the rigors of shoe sole production, ensuring that these machines can handle the high demands of continuous industrial use.

Advantages of Modern Sole Machinery

Modern vertical shoe sole machines bring numerous advantages to the footwear industry. They enhance production speed, improve sole quality, and offer the flexibility to work with a range of materials. These machines contribute to the scalability of shoe manufacturing operations, allowing producers to meet market demands efficiently.

Choosing the Right Machine

Selecting the appropriate vertical shoe sole machine requires careful consideration of the workspace and production goals. It is essential to assess the machine size, operational features, and compatibility with existing production lines to ensure a seamless integration into the shoe manufacturing process.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4