Popular in your industry

Top categories

About used lapping machines

Understanding Used Lapping Machines

Lapping machines are precision tools used for finishing surfaces to a high degree of accuracy and smoothness. Used lapping machines offer an economical alternative to new equipment, providing the same functionality at a reduced cost. These machines are employed in various industries, including aerospace, automotive, and electronics, where precise surface refinement is crucial.

Types and Applications

There is a diverse range of lapping machine used in the industry, each suited for specific tasks. Metal polishing machines are common for creating a mirror-like finish on metals, while surface grinding machines are used to produce a smooth finish on flat surfaces. Chamfering machines, on the other hand, are used to create beveled edges for joining parts. These machines find applications in manufacturing plants and machinery repair shops, and are also utilized in construction for precision work.

Features and Materials

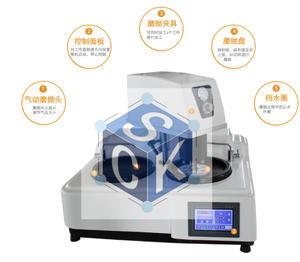

The construction of a lapping machine dictates its suitability for certain tasks. Typically, these machines include components such as motors and bearings, and some models are equipped with engines. The materials used in used lapmaster lapping machine are designed to withstand the rigors of grinding and polishing, ensuring longevity and consistent performance. The features of these machines often include ease of operation, competitive pricing, and multifunctional capabilities, catering to a wide range of surface finishing needs.

Advantages of Opting for Used Equipment

Choosing a used slant cabber or lapping machine can be advantageous for businesses looking to expand their capabilities without incurring the high costs associated with new machinery. These machines are tested for performance and often come from reputable sources, ensuring they meet the necessary operational standards. Additionally, opting for used equipment is a sustainable choice, contributing to the reduction of waste and the conservation of resources.

Selecting the Right Used Lapping Machine

When selecting a used lapping machines, it is important to consider the specific requirements of the task at hand. Factors such as the size of the machine, the type of surfaces it can handle, and its condition should be evaluated. It is also crucial to consider the availability of spare parts and the machine's compatibility with existing equipment in the facility.

Conclusion

In conclusion, used lapping machines are a cost-effective and reliable option for businesses in need of surface finishing tools. With a variety of types and features available, these machines can be a valuable addition to any operation focused on precision and quality. By selecting the appropriate machine and ensuring it meets operational standards, businesses can benefit from the integration of these used tools into their manufacturing or repair processes.