Popular in your industry

Related Searches:

Top categories

About tin cap sealing machine

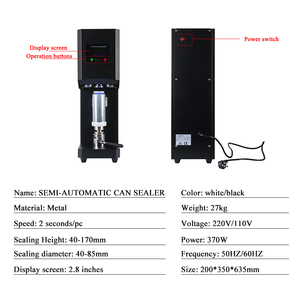

Tin Cap Sealing Machine: An Overview

Tin cap sealing machines are essential tools in the packaging industry, designed to securely seal containers with various contents. These machines are pivotal for maintaining the integrity and quality of products within containers such as bottles, cartons, and especially tin cans. The versatility of these machines allows them to be applied across a multitude of sectors, including the chemical, pharmaceutical, and food industries.

Types and Applications

The range of tin cap sealing machines includes manual tin cap sealing machines and automated variants, each serving distinct operational scales and requirements. For instance, the 15kg tin metal cap hand sealing machine is a popular choice for small-scale operations, offering a cost-effective and user-friendly solution for sealing. On the other hand, automated machines cater to larger production needs, where efficiency and volume are critical.

Features and Materials

Constructed from durable materials, tin cap sealing machines are built to withstand the rigors of industrial environments. The design of these machines prioritizes ease of use and safety, ensuring that they can be operated with minimal training. Features may include adjustable sealing parameters to accommodate 15 kg tin caps, ensuring a versatile application range.

Advantages of Using Tin Cap Sealing Machines

The advantages of using these machines are manifold. They provide a reliable seal that can withstand pressure, temperature, and time, which is crucial for preserving product quality. Furthermore, the precision offered by a 15kg oil tin sealing machine ensures that seals are consistent, which is vital for consumer trust and brand reputation.

Selection Criteria

Selecting the right tin cap sealing machine involves analyzing specific features such as the machine's capacity, compatibility with different tin cap sizes, such as the oil tin cap sealing machine, and the nature of the sealing process. It is essential to consider the specific needs of the operation, whether it requires a hand tin cap sealing machine for more artisanal, small-batch production or a fully automated solution for high-volume output.

Ensuring Quality and Performance

Quality assurance is a critical aspect of the manufacturing process for tin cap sealing machines. Standard test methods are applied to assess the strength and durability of the seals produced. Only after these machines meet stringent verification and validation standards are they considered suitable for the market. This rigorous testing protocol ensures that the machines provide optimum performance and reliability.