Popular in your industry

Related Searches:

Top categories

About the old rice mill

The Old Rice Mill: An Overview

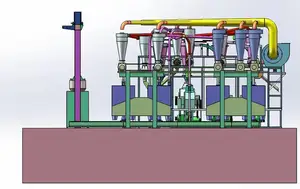

The term "the old rice mill" conjures images of traditional rice processing, where the art of milling was as integral to the culture as the rice itself. This category encompasses various machines designed to transform paddy into its consumable form by removing husks and bran layers. While the technology has evolved, the essence of milling remains, ensuring that the rice is prepared for consumption with its taste and nutritional value intact.

Types and Applications of Rice Mills

Rice mills come in different types, each serving a specific milling process. The single-pass mill, a classic example of the old rice mill, is known for its simplicity, directly converting paddy to white rice in one go. On the other hand, multi-pass mills offer a more refined approach, separating husks and bran in distinct stages. These mills cater to a variety of applications, from small-scale farming to larger, commercial rice production, adapting to the diverse needs of the global rice industry.

Features and Materials

Modern iterations of the old rice mill are constructed with a blend of traditional design and contemporary materials. Durability is a cornerstone, with components typically made from robust metals that withstand the rigors of rice milling. The design of these machines prioritizes efficiency, with features that facilitate easy operation and maintenance, reflecting an understanding of the milling process honed over generations.

Advantages of Modern Rice Milling

The advantages of modern rice milling are numerous. The process not only expedites the production of edible rice but also enhances the final product's quality. By employing advanced milling techniques, the rice produced retains more of its nutritional content and offers a better texture and flavor profile. Furthermore, the efficiency of modern mills reduces waste, contributing to more sustainable production practices.

Operational Considerations

When operating the old rice mill, several considerations are paramount to ensure smooth processing. The condition of the machine's parts, such as the transmission belt, is critical to performance. Proper lubrication of moving parts is essential to prevent friction and wear. Additionally, the quality of input—ensuring rice is free from stones and has the correct moisture content—is vital to avoid damage to the machine and to guarantee efficient milling.

Choosing the Right Rice Mill

Selecting the appropriate rice mill is crucial for businesses in the rice sector. Factors such as capacity, efficiency, and the specific type of milling required should guide the decision. Platforms like Alibaba.com offer a diverse array of milling machines, connecting buyers with a global network of suppliers. This ensures that businesses can find a milling solution that aligns with their operational needs and objectives.