Popular in your industry

Related Searches:

Top categories

About steel plate groove machine

Introduction to Steel Plate Groove Machines

Steel plate groove machines are specialized industrial equipment designed for creating precise grooves in steel plates. These machines are integral to various manufacturing processes, where they prepare metal components for welding and assembly. Utilized in a range of industries from construction to automotive manufacturing, these machines enhance the structural integrity of metal joints.

Types and Applications

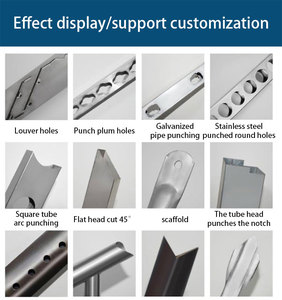

The versatility of steel plate groove machines is evident in their various types, each suited to specific applications. CNC grooving machines offer automated precision, ideal for high-volume production environments. Tile making machinery often incorporates grooving functions to facilitate the easy assembly of tiles. Chamfering machines, while primarily used for beveling edges, can also be equipped to groove steel plates. These machines serve industries such as infrastructure development, where steel components require grooving for major projects.

Features and Materials

Steel plate groove machines are designed with robust features to handle the rigors of metal fabrication. They are constructed from durable materials capable of withstanding the stress of cutting through steel. The machines typically include components like motors, engines, and pumps, which are selected for their reliability and performance in industrial settings. The construction of these machines ensures they can deliver precise grooves consistently over extended periods.

Advantages of Modern Grooving Technology

The latest advancements in grooving technology have equipped steel plate groove machines with enhanced capabilities. These include improved precision in groove dimensions, increased speed of operation, and better user safety. The efficiency of modern machines reduces waste and energy consumption, contributing to more sustainable manufacturing practices. Additionally, the precision of these machines minimizes the need for secondary finishing processes, saving time and resources.

Selection Considerations

When selecting a steel plate groove machine, factors such as material compatibility, groove dimensions, and machine capacity are critical. Buyers should consider the specific requirements of their manufacturing processes, including the thickness and type of steel plate to be grooved. It is also important to evaluate the space available for the machine, as well as the power supply compatibility.

Maintenance and Durability

Maintenance is a key factor in ensuring the longevity of steel plate groove machines. Regular servicing helps to prevent mechanical failures and maintain operational accuracy. The durability of these machines is often reflected in their design, which should facilitate easy access to components for maintenance and repairs. Buyers are encouraged to consider the availability of spare parts and technical support when choosing a machine.