Introduction to Stainless Steel Brazing Rods

Brazing is a metal-joining process that involves the melting and flowing of a filler metal into the joint between two close-fitting parts. Stainless steel brazing rods are a specific type of filler metal used for this purpose, designed to effectively join stainless steel components. These rods are selected based on their compatibility with the base metals, melting point, and the environment in which the joined metal will operate.

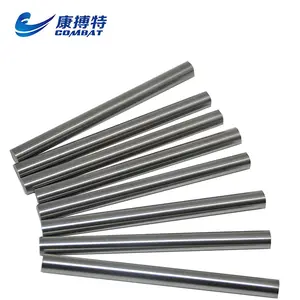

Types and Applications

There are various types of stainless steel brazing rods, each tailored for specific applications. Brazing stainless steel with brass rod is common for joining stainless steel to other metal types, offering strong, corrosion-resistant joints. Stainless brazing rod varieties include those designed for general-purpose use, while others, like copper to stainless steel brazing rod, are formulated for specific metal combinations. These rods find applications in industries ranging from automotive to food processing equipment, where durable and hygienic joins are essential.

Features and Materials

The composition of stainless steel brazing rods typically includes a mixture of metals such as silver, copper, and zinc. This composition is crucial as it determines the melting point and flow characteristics of the rod. For instance, ss brazing rod is engineered to have a lower melting point than the base metals, ensuring the integrity of the workpiece is maintained during the brazing process. Additionally, bronze brazing stainless steel rods are preferred for their strength and wear resistance in heavy-duty applications.

Advantages of Using Stainless Steel Brazing Rods

Using stainless steel brazing rods offers several advantages. They provide strong, sealed joins that are resistant to various forms of corrosion and extreme temperatures. Moreover, brazing stainless steel with propane is a cost-effective method that does not require the high temperatures of welding, making it accessible for a wide range of applications. The versatility of these rods allows for joining dissimilar metals, such as with stainless steel to copper brazing rod, which is particularly beneficial in complex assemblies.

Selecting the Right Brazing Rod

Choosing the correct brazing rod is essential for the success of the joining process. Factors to consider include the thermal expansion rates of the base metals, the joint design, and the service conditions of the final product. For example, a brazing rod for copper to stainless steel is specifically formulated to accommodate the different expansion rates of these metals, ensuring a durable bond.

Conclusion

In conclusion, stainless steel brazing rods are a critical component in the metal joining process. Their selection and application require understanding the materials involved and the operating conditions of the final product. With a variety of rods available, it is possible to achieve strong, durable, and corrosion-resistant joints for a multitude of industrial applications.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4