Popular in your industry

Related Searches:

Top categories

About silicone filling machine

Silicone Filling Machine: An Overview

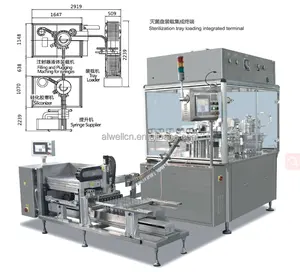

The realm of industrial machinery has seen significant advancements with the introduction of silicone filling machines. These machines serve a critical role in the packaging and production lines across various industries, providing an efficient solution for handling viscous materials. The silicone filling machine category encompasses a range of equipment designed to fill silicone into various containers with precision and efficiency.

Types and Applications

Within this category, the silicone cartridge filling machine is specifically tailored for packaging silicone in cartridges, commonly used in the construction and automotive sectors. For larger scale operations, the silicone sealant filling machine offers a robust solution for filling bulk quantities. In the pharmaceutical and cosmetic industries, the silicone tube filling machine is preferred for its ability to handle smaller, more precise fills. Each type of machine is engineered to meet the specific demands of its application, ensuring that businesses can find a suitable match for their production requirements.

Features and Materials

The construction of these machines often involves the use of durable materials that can withstand the corrosive nature of silicone and other substances. Stainless steel components are common, providing longevity and ease of maintenance. Advanced models of the silicone sealant cartridge filling machine may include programmable logic controllers (PLCs) and touch screen interfaces for enhanced control and monitoring of the filling process.

Advantages of Utilization

Utilizing a silicone filling machine in production lines translates to increased efficiency and consistency in product output. The precision offered by these machines minimizes waste and ensures that each container is filled to the exact required level. This level of accuracy is particularly beneficial when dealing with high-cost materials, where overfilling can lead to significant product loss. Moreover, the automation of the filling process reduces the need for manual labor, thereby streamlining operations and potentially increasing profitability.

Compatibility and Maintenance

The compatibility of silicone filling machines with various accessories enhances their functionality. Accessories can include nozzles, conveyors, and sealing systems, which together create a cohesive production line from filling to final packaging. Maintenance is simplified due to the intuitive design of these machines, allowing for easy cleaning and quick repairs without extensive downtime.

Conclusion

In conclusion, the silicone filling machine category offers a diverse range of solutions to meet the needs of businesses looking to enhance their production capabilities. From the silicone cartridge filling machine to the silicone tube filling machine, these machines are designed to improve the efficiency, accuracy, and reliability of filling processes across various industries.