Popular in your industry

Related Searches:

Top categories

About shampoo bottle blow molding

Introduction to Shampoo Bottle Blow Molding

Shampoo bottle blow molding is a specialized manufacturing process used to produce durable and versatile containers for the personal care industry. This technique involves shaping plastic into bottles that are ideal for containing liquids such as shampoos. The process is favored for its efficiency in creating uniform products in large volumes.

Types and Applications

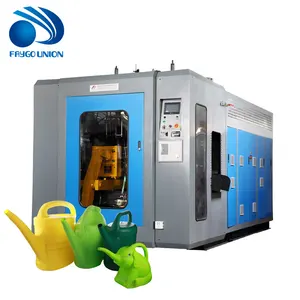

The blow molding machines cater to a range of applications, from personal care to household cleaning products. They are capable of producing a variety of bottle sizes and shapes, ensuring versatility across different product lines. The adaptability of these machines allows for the production of containers not just for shampoos but also for conditioners, body washes, and other liquid personal care items.

Features and Materials

Shampoo bottle blow molding equipment is engineered to handle various plastic materials, including PET, PE, and PVC, which are commonly used for their flexibility and strength. Advanced models feature energy-saving operations, contributing to a more sustainable production process. The machinery is designed with user-friendly controls, making the operation more streamlined and less labor-intensive.

Advantages of Blow Molding for Shampoo Bottles

Utilizing blow molding for shampoo bottles offers manufacturers the advantage of creating high-quality containers with precision and repeatability. The automated nature of the process ensures a consistent product output with minimal waste, which is crucial for large-scale production. Additionally, the ability to customize bottle designs allows for a wide range of product differentiation, which is essential in the competitive personal care market.

Choosing the Right Machine

Selecting the appropriate blow molding machine is critical for meeting production demands. Factors such as container volume, shape complexity, and material type should be considered. Suppliers on Alibaba.com provide a variety of machines, each with different capabilities to match specific production requirements. It is important to assess the specifications of each machine to ensure it aligns with the intended production goals.

Environmental Considerations

Modern shampoo bottle manufacturing processes are increasingly incorporating eco-friendly practices. Machines that offer reduced energy consumption not only lower operational costs but also support environmental sustainability. The choice of materials can also impact the recyclability of the finished bottles, with many manufacturers opting for plastics that can be easily recycled to minimize environmental impact.