Popular in your industry

Related Searches:

Top categories

About printing ink mixer

Introduction to Printing Ink Mixers

Printing ink mixers are essential equipment in the printing industry, specifically designed to homogenize and blend various types of inks used in printing processes. These mixers play a crucial role in ensuring the consistency and quality of the ink, ultimately affecting the final output of the printing job. Whether it's screen printing ink or plastisol ink, having a reliable ink mixer is vital for achieving optimal results.

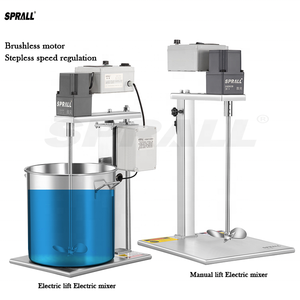

Types of Printing Ink Mixers

There are several types of printing ink mixers available on Alibaba.com to cater to different printing requirements. Screen printing ink mixers are specifically designed for the unique characteristics of screen printing inks, providing efficient mixing and blending capabilities. On the other hand, plastisol ink mixers are tailored for plastisol inks, known for their durability and vibrant colors. By exploring the range of ink mixers on the platform, buyers can find the perfect match for their specific ink types.

Technical Specifications and Features

When considering a printing ink mixer, it's essential to look at the technical specifications and features to ensure it meets your printing needs. Features like variable speed control, adjustable mixing time, and robust construction are crucial for efficient ink mixing. Additionally, the power capability, mixing capacity, and compatibility with different ink viscosities are key technical specifications to evaluate before making a purchase decision.

Advantages of Ink Mixing Systems

Investing in a high-quality ink mixing system offers numerous advantages for printing businesses. These systems streamline the ink preparation process, saving time and labor costs. They also ensure consistent ink quality, leading to improved print results and customer satisfaction. Moreover, ink mixing systems contribute to waste reduction by accurately measuring and mixing the required ink quantities.

Choosing the Right Ink Mixer

When selecting an ink mixer for your printing operations, consider factors such as the types of inks you use, the volume of printing work, and the desired level of automation. For businesses dealing with a variety of inks, a versatile mixer that can handle different ink types and viscosities is recommended. Furthermore, opt for a mixer with user-friendly controls and easy maintenance to enhance operational efficiency.

Use Scenarios of Ink Mixers

Ink mixers find applications across various printing processes, including screen printing, offset printing, and flexography. Whether mixing UV inks, water-based inks, or solvent-based inks, the versatility of ink mixers makes them indispensable in the printing industry. From small-scale print shops to large commercial printing facilities, ink mixers play a critical role in ensuring smooth and efficient ink preparation.

Maintenance of Ink Mixing Systems

To prolong the lifespan and efficiency of your ink mixing system, regular maintenance is essential. This includes cleaning the mixer components, checking for wear and tear, and ensuring proper calibration of the mixing settings. Additionally, following the manufacturer's guidelines for maintenance schedules and using recommended cleaning solutions can help prevent breakdowns and ensure consistent performance.

Conclusion

Printing ink mixers are fundamental equipment for achieving consistent and high-quality prints in the printing industry. By understanding the types, technical specifications, advantages, and maintenance requirements of ink mixers, buyers can make informed decisions when selecting the right equipment for their printing operations. Alibaba.com offers a wide range of ink mixers to cater to diverse printing needs, ensuring that businesses can find the perfect solution to enhance their printing processes.