Introduction to Plasma Surface Treatment Machines

Plasma surface treatment machines are integral to modern manufacturing and finishing processes. These devices harness the power of plasma technology to modify the surface properties of various materials, enhancing adhesion, cleaning substrates, and activating surfaces for further processing. The versatility of plasma treatment machines makes them suitable for a range of industries, from printing to automotive manufacturing.

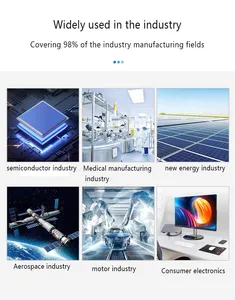

Types and Applications

The types of plasma surface treatment machines vary, including options like plasma corona treatment machines and plasma nitriding machines. Each type serves a specific function, from improving paint adhesion and surface wettability to hardening and nitriding surfaces for extended wear resistance. These machines are commonly found in manufacturing plants, printing shops, and advertising companies, catering to the needs of businesses in India, Vietnam, and Indonesia, among others.

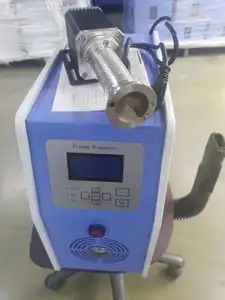

Features and Technical Specifications

Plasma surface treatment machines come equipped with various features such as advanced motor systems, programmable logic controllers (PLCs), and engines designed to deliver precise treatment. The technical specifications may include adjustable power settings, treatment width options, and compatibility with different materials, ensuring a broad range of applications from skin rejuvenation in medical devices to wrinkle removal and acne treatment in cosmetic tools.

Materials and Design

The construction of plasma treatment machines involves materials that can withstand high-intensity plasma environments. Durable metals and composites are used to ensure longevity and consistent performance. The design of these machines focuses on user safety, operational efficiency, and minimal maintenance requirements, making them a reliable component in any industrial setting.

Advantages of Using Plasma Treatment

Utilizing a plasma surface treatment machine offers numerous advantages, such as enhanced surface cleanliness, increased bonding properties, and the elimination of organic contaminants. These benefits are crucial for industries where precision and durability of surface treatments are paramount. Moreover, plasma treatment is an environmentally friendly option, as it reduces the need for harsh chemical processes.

Choosing the Right Machine

Selecting the appropriate plasma corona treatment machine or plasma nitriding machine depends on the specific requirements of the task at hand. Factors to consider include the type of material to be treated, the desired outcome, and the scale of production. While Alibaba.com does not endorse any particular brand or make guarantees, the platform offers a comprehensive listing of suppliers to help businesses find a machine that aligns with their operational needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4