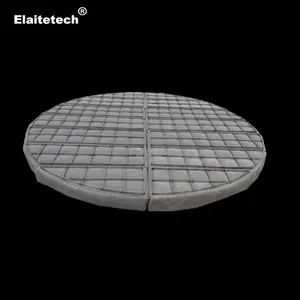

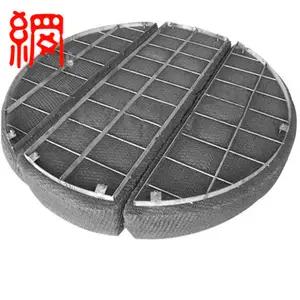

Mist Eliminator in Boiler Steam Drum: An Overview

The mist eliminator in boiler steam drum is a critical component in steam-generating systems, designed to remove excess moisture from steam. This ensures that only dry steam is delivered for various industrial applications, enhancing efficiency and protecting downstream equipment from corrosion and damage.

Types and Applications

There are several types of mist eliminators used in boiler steam drums, including mesh pad, vane-type, and fiber bed mist eliminators. Each type serves the same fundamental purpose but operates optimally under different conditions and applications. These devices are essential in industries ranging from petrochemical to power generation, where controlling moisture in steam is crucial.

Features and Materials

A mist eliminator in boiler steam drum is characterized by its corrosion resistance and durability, often made from materials like stainless steel, polypropylene, or other alloys suited for high-temperature and high-pressure environments. The design of these eliminators allows for maximum droplet capture with minimal pressure drop across the system.

Advantages of Using Mist Eliminators

Incorporating a mist eliminator into a boiler steam drum offers numerous advantages, such as improved thermal efficiency, reduced boiler water carryover, and extended life of steam turbines. By ensuring the delivery of dry steam, these eliminators also contribute to the consistent quality of the end product in manufacturing processes.

Selection Criteria

Selecting the appropriate mist eliminator involves considering factors such as the size of the steam drum, steam flow rate, and the specific requirements of the application. It is crucial to choose a mist eliminator that matches the operational demands to achieve optimal performance.

Maintenance and Sustainability

Regular maintenance of a mist eliminator in boiler steam drum is essential for sustaining its performance and longevity. Proper care includes routine inspections and cleaning to prevent fouling and ensure efficient operation. Sustainability is also a key consideration, with many mist eliminators designed for energy efficiency and minimal environmental impact.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4