Calender Sublimation Machine Big Discount 600mm Drum Diameter Touch Screen Panel Roller Sublimation Heat Transfer Press Machine Calender

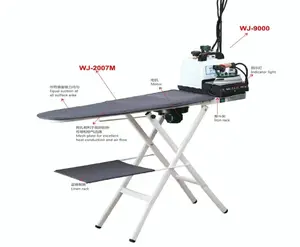

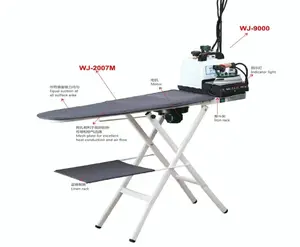

Hoop Huibu Steam Iron Press With Boiler Table Cloth Suit Ironing Machines For Garment Laundromat Machine Shop

In the fast-paced world of fashion and garment care, efficiency is not just a goal—it's a necessity. The latest ironing press machines are revolutionizing the industry, offering unprecedented speed, precision, and ease of use. From the humble beginnings of metal tools heated over fire to the sophisticated, automated systems of today, these machines have evolved to become integral to the garment business. In this article, we explore the journey of ironing press machines, their diverse types available on Alibaba.com, and the key features that can help maximize efficiency in your garment business. Whether you're a small boutique or a large-scale operation, understanding the evolution, types, and benefits of these machines is crucial in streamlining your processes and enhancing productivity.

The history of ironing press machines is a testament to human ingenuity and the evolution of garment care. Originating from simple metal tools heated over fire in the 1300s, these devices have undergone significant transformations. The 'flatiron' or 'sad iron' was a staple in households, requiring frequent reheating to maintain the necessary temperature for smoothing garments. By the 1800s, metal technology advancements led to the creation of flatirons that could be heated on stoves, offering a cleaner and more efficient process.

The late 19th century saw the introduction of gas irons, which were lighter and easier to use than their heavy predecessors. However, the true revolution came with the electrification of homes, which paved the way for the electric iron. Patented in the 1880s, the electric iron featured built-in coils, eliminating the constant need for reheating. The early 20th century brought further innovation with electric cords and thermostats for temperature control, significantly enhancing the ironing experience.

Subsequent decades saw the introduction of steam irons, which incorporated water vapor to ease the pressing of dry material, and by the mid-20th century, irons with both wet and dry capabilities emerged. The evolution of ironing press machines continues, with modern iterations focusing on improved sole plate materials for durability and better temperature and steam regulation, ensuring that these tools remain essential in garment care.

Alibaba.com showcases a diverse range of ironing press machines designed to meet the varied needs of the garment industry. From robust commercial linen laundry steam press machines, ideal for pressing cloth in high-volume settings, to the more specialized iron plate hand operation machines that cater to precise ironing and folding requirements. The platform also features hydraulic metal shear machines, which combine shearing and bending functionalities, demonstrating the multifunctional capabilities of modern ironing equipment.

For businesses seeking portability, manufacturers offer compact, fast-heating ironing press machines, suitable for commercial sheet ironing. These machines are designed for quick setup and efficient operation. Additionally, fabric steam press irons and garment steamers are available for both home and commercial use, providing versatility for different ironing preferences. The range includes large, industrial-sized machines as well as mini portable household variants, ensuring there is a solution for every scale of operation.

Innovations in the sector are represented by automatic socks ironing machines and other automated presses that streamline the ironing process. The assortment of ironing machines extends to include air suction ironing tables and industrial washing machines with integrated dryers and ironing functions, highlighting the industry's move towards all-in-one solutions. For businesses prioritizing space-saving options, stackable commercial washers and dryers are also featured, which combine functionality with a compact footprint.

Industrial steam iron presses are designed to handle shaped garments and large items efficiently. These machines are equipped with a heat generator that distributes heat through two plates, or bucks, which are available in versatile designs to accommodate various garment types. The pneumatic system of these presses ensures ease of use, with a high-pressure output that can be fully adjusted. The control of the machine is simplified with push buttons for operations such as the lowering of the upper buck and the entry of steam. Safety features include a protective frame, and the machines can be either stand-alone with an electric boiler and integrated compressor or connected to an external steam and compressed air network. This adaptability makes the iron press machine a forward-thinking choice for businesses handling high volumes of garments.

The introduction of the Unit Production System revolutionized garment manufacturing, offering a method to produce garments more efficiently. This system minimizes the time traditionally required to assemble garments, allowing for a seamless transition between different production stages. By integrating such systems, garment businesses can significantly enhance their production efficiency.

The use of advanced conveyors and control software in garment production systems ensures that the workflow is continuous and that machines, such as ironing presses, are utilized optimally. This coordination means that each garment is ironed at the precise time it's needed in the production line, contributing to a streamlined process that reduces bottlenecks and increases output.

Adopting modern systems like these can be a strategic investment for businesses specializing in diverse clothing items, from shirts to made-to-measure suits. The flexibility and adaptability of such systems make them suitable for various garment types, enhancing the overall productivity of the ironing process within the garment production cycle.

The integration of automation and technology in ironing press machines has significantly transformed the garment industry. A prime example of this advancement is the automated ironing machine that is capable of pressing a substantial number of shirts in a short period. This machine exemplifies the efficiency of modern ironing technology with its ability to iron multiple shirts concurrently, a feature that underscores the role of automation in enhancing productivity.

The use of a touch screen interface simplifies the operation, allowing for a seamless interaction between the user and the machine. This user-friendly interface is indicative of the technological strides being made in the industry, aiming to reduce manual input and streamline the ironing process.

Moreover, the design of these machines often includes the capability to fold into a more compact form, addressing storage concerns in professional settings. The emphasis on space-saving design without compromising functionality reflects the thoughtful integration of technology in the development of modern ironing presses. Such innovations are geared towards improving the workflow and profitability of garment businesses, showcasing the pivotal role of automation and smart design in the evolution of ironing equipment.

Selecting the appropriate ironing press machine for your business involves considering both material and size to ensure it meets your specific needs. For establishments with smaller volumes of flatwork garments, such as restaurants or small hotels, a compact ironer may be sufficient. These machines are designed to handle smaller quantities efficiently, making them suitable for businesses with limited space and lower workloads.

Conversely, medium-sized operations like hospitals and larger restaurants, which deal with a higher volume of items such as bed linens, tablecloths, and uniforms, may require larger flatwork ironers. These machines are built to accommodate a greater quantity of garments, facilitating workflow and enhancing productivity.

The size of the ironer is also a crucial factor, especially for businesses with space constraints. Wall-mounted ironers, for example, offer the convenience of feeding and collecting linen from the front, saving valuable space. Some models can also function as pass-through machines, providing additional flexibility for the layout of your laundry area.

Ultimately, the choice of an ironing press machine on platforms like Alibaba.com should be tailored to the specific requirements of your business, taking into account the volume of garments to be processed and the available workspace.

Upgrading to the latest ironing press machines introduces a range of benefits for both domestic and commercial environments. Modern presses are designed to be more efficient, reducing ironing time significantly. For instance, using a steam press machine can halve the time spent on ironing. These advanced machines come with multiple settings for dry and steam pressing, accommodating various fabric types and ironing needs.

The latest models are also built for robustness and reliability, suitable for heavy-duty industrial use. They offer a superior finish, which is especially beneficial for businesses like dry cleaners, ironing services, laundries, and hospitality industries. The ability to iron multiple layers or large items such as king-size bedding demonstrates the capacity of these machines to handle substantial volumes, making them a smart investment for businesses looking to enhance productivity.

Furthermore, the new range of ironing presses is designed with user-friendly controls, making them simple to operate. This ease of use, combined with their efficient performance, means that fabrics are treated gently, extending their lifespan. The versatility of color options and the inclusion of accessories like spare covers and pressing cushions add to the appeal of these modern ironing solutions.

Investing in a sophisticated ironing press machine can significantly impact the productivity and efficiency of garment businesses. These machines are designed to handle a variety of textiles, from heavy-duty fabrics to delicate items, ensuring a smooth finish without the need for pre-dampening. The ability to iron garments while seated and without exerting physical pressure reduces the strain on operators, leading to a more comfortable and sustainable working environment.

These models boast a large roller width, facilitating the ironing of larger items like sheets and tablecloths with ease, while its quick heat-up time and variable speed settings streamline the ironing process. The even distribution of steam and heat from the roller ensures high-quality results, even on the most stubborn wrinkles. With settings tailored for different materials, the machine offers versatility, allowing for both dry and steam ironing. The energy-efficient design, including an auto shut-off feature, contributes to operational savings over time.

Maintenance of these machines is minimal, which, when coupled with their durable construction, translates into a lower total cost of ownership. The initial investment in such ironing equipment is offset by the longevity and performance efficiency, making it a cost-effective solution for businesses looking to enhance their garment finishing processes. Additionally, the use of distilled or de-ionized water is recommended but not mandatory, offering flexibility in operation and potential savings on consumables.

Maintaining your ironing press machine is crucial for ensuring its longevity and optimal performance. Regularly following the maintenance guidance provided with your product is key. It's important to note that warranties typically do not cover damage from wear and tear, issues caused by limescale, or misuse of the equipment. To prevent common problems, such as limescale build-up, which can lead to faults if not addressed, it's essential to service the machines regularly, especially when used for prolonged hours. Taking these proactive steps can help in identifying potential issues before they escalate into costly repairs.

The garment industry's landscape is continually reshaped by technological advancements, and the latest ironing press machines stand at the forefront of this transformation. With a rich history of innovation, these machines have evolved to meet the demands of modern garment care, offering a variety of types to suit different business needs. From the efficiency of automated presses to the adaptability of size and material considerations, upgrading to the latest models provides a competitive edge. The investment in high-quality ironing equipment pays dividends in productivity and garment finish quality. Moreover, maintaining these machines with regular care ensures their longevity and optimal performance. In conclusion, embracing the latest in ironing press technology is not just about enhancing efficiency; it's about investing in the future of your garment business, ensuring that every press and steam leads to perfection, garment after garment.