Popular in your industry

Related Searches:

Top categories

About eye drop filling sealing machine

Introduction to Eye Drop Filling Sealing Machines

Eye drop filling sealing machines are specialized equipment designed for the pharmaceutical industry, catering to the precise requirements of eye drop production. These machines are integral to the packaging process, ensuring that the product is filled and sealed in a sterile and efficient manner. The category encompasses a range of machinery, from manual to fully automatic systems, tailored to meet diverse operational scales and needs.

Types of Eye Drop Filling Sealing Machines

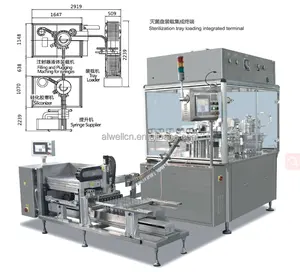

The variety of eye drop filling sealing machines includes manual, semi-automatic, and automatic models. Manual fillers are ideal for startups and small-scale operations, offering a cost-effective solution without the need for electricity. Semi-automatic and automatic machines cater to medium and large-scale production, enhancing throughput with minimal human intervention. Each type is designed to handle the delicate nature of eye liquids with precision.

Features and Applications

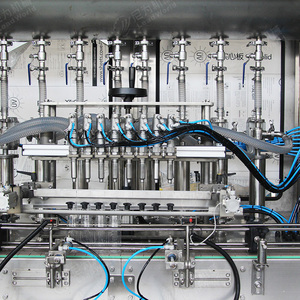

These machines are not one-size-fits-all; they are tailored to accommodate different types of eye drop solutions. Features may include vacuum prevention to avoid contamination, precision filling nozzles for accurate dosage, and tamper-evident sealing capabilities. The application of these machines spans across various environments, from small laboratories to large pharmaceutical factories, each benefiting from the automation and consistency provided by these specialized machines.

Materials and Advantages

Constructed from materials compatible with pharmaceutical standards, such as stainless steel, eye drop filling sealing machines are built for durability and cleanliness. The advantages of using these machines are manifold, including increased production speed, improved accuracy, and reduced waste. They are designed to maintain the integrity of the eye drops, ensuring that the product remains free from contaminants throughout the filling and sealing process.

Choosing the Right Machine

Selecting the appropriate eye drop filling sealing machine requires an understanding of your production needs. Factors to consider include the viscosity of the filling material, the required production capacity, and the level of automation needed. It is essential to assess the specific characteristics of the eye drop solution to ensure compatibility with the machine's filling and sealing mechanisms.

Enhancing Production with the Right Equipment

In conclusion, the right eye drop filling sealing machine can significantly enhance production efficiency. Alibaba.com offers a diverse selection of these machines, allowing businesses to find the perfect match for their production requirements. By automating the filling and sealing process, pharmaceutical companies can achieve higher standards of product safety and consistency, which are paramount in the industry.