Popular in your industry

Related Searches:

Top categories

About end milling machine for aluminum

Introduction to End Milling Machines for Aluminum

End milling machines for aluminum are specialized equipment designed for precision machining of aluminum and its alloys. These machines are integral to industries where aluminum parts are required, such as aerospace, automotive, and construction. The end milling machine for aluminum stands out for its ability to handle various milling tasks with accuracy and speed.

Types and Applications

The versatility of end mills for aluminum is reflected in the variety of types available. From solid carbide end mills for aluminum known for their rigidity and longevity, to high performance end mills for aluminum that cater to high-speed applications, the range is extensive. These machines are adept at creating intricate parts for machinery, executing fine detail work in metal fabrication, and producing customized aluminum components.

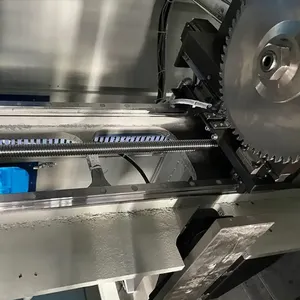

Features and Materials

An end milling machine for aluminum is engineered with features that enhance performance and user experience. The use of aluminum milling bits and carbide end mills for aluminum ensures precision in cutting and shaping materials. The construction of these machines often involves robust materials that withstand the stresses of milling, contributing to the machine's longevity and consistent performance.

Advantages of Modern Milling Technology

Modern end milling machines for aluminum are designed to be user-friendly and energy-efficient. They offer advantages such as ease of operation and the ability to perform both cold and hot pressing, which is crucial in applications like door frame manufacturing. Additionally, the adaptability of machines, such as long reach end mills for aluminum and extra long end mills for aluminum, allows for working on diverse projects without the need for extensive workspace reconfiguration.

Operational Efficiency and Maintenance

Operational efficiency is a hallmark of the CNC end mills for aluminum, which are known for their automated precision. These machines require minimal manual intervention, reducing the likelihood of errors and increasing production rates. Maintenance is also simplified, with easy-to-clean components that help maintain a hygienic work environment.

Choosing the Right Machine

Selecting the right end milling machine for aluminum involves considering the specific requirements of your projects. Factors such as the size of the aluminum parts, the complexity of the milling tasks, and the volume of production should guide your choice. For those dealing with tougher materials or high-volume jobs, aluminum roughing end mills might be the preferred option due to their aggressive cutting capabilities and durability.

In conclusion, an end milling machine for aluminum is a significant investment for businesses looking to enhance their aluminum machining processes. With a range of types and features designed to meet various production needs, these machines are a cornerstone in the manufacturing of aluminum parts. When considering a purchase, it is essential to evaluate the machine's capabilities against the specific demands of your applications to ensure you select a machine that aligns with your operational goals.