Understanding the Role of Dies in Hydraulic Bending Machines

The die for hydraulic bending machine is a critical component in shaping and fabricating metal sheets. These dies are the tools that, when paired with hydraulic bending machines, apply the necessary force to bend metal into precise angles and shapes. The selection of the appropriate die is crucial for achieving the desired bend radius and minimizing material springback.

Types and Materials of Dies

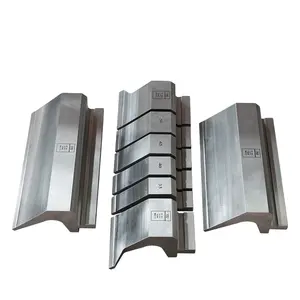

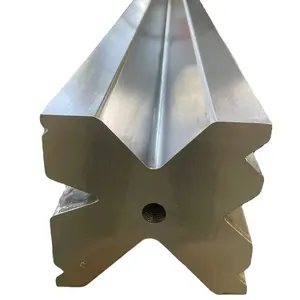

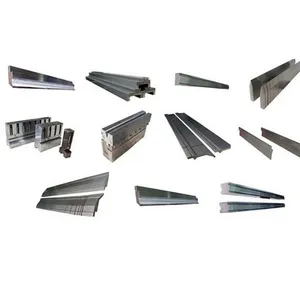

Dies used in hydraulic bending machines come in various types, each designed for specific bending operations. Standard dies, acute angle dies, and gooseneck dies are among the common types that cater to different bending requirements. The materials used for these dies, such as hardened steel or iron, are selected based on durability, wear resistance, and the ability to withstand repeated high-pressure contact with metal workpieces.

Applications and Features

The application of hydraulic press brake tooling extends across industries from automotive to aerospace, where precise metal forming is essential. Features such as the V-opening width and the die's height are tailored to handle various thicknesses and types of metal. Additionally, the integration of features like standard lift bars and uniform clamp slots across dies enhances versatility and interchangeability in production processes.

Advantages of Optimized Die Design

An optimized press brake die design can significantly influence production efficiency and part quality. By standardizing certain elements of the die, manufacturers can reduce setup times and streamline their operations. Furthermore, a well-designed die minimizes wear on the hydraulic bending machine, thereby extending its service life and reducing maintenance needs.

Selection Considerations

When selecting a bending machine mold, it is essential to consider the material compatibility and the specific requirements of the bending process. Factors such as the workpiece material's hardness, the bending angle precision, and the complexity of the design play a pivotal role in the selection process. Suppliers on Alibaba.com offer a diverse range of dies, providing ample options to find the suitable match for your bending needs.

Collaboration with Suppliers

Collaborating with suppliers on Alibaba.com for your sheet metal bending dies needs ensures that you receive a product tailored to your specifications. Suppliers can assist in refining the die design, conducting test runs to ensure the die performs as intended. This collaborative approach ensures that the final product meets the operational demands without compromising on the quality of the bent components.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4