Popular in your industry

Related Searches:

Top categories

About die cut kt board

Introduction to Die Cut KT Board

Die cut KT boards are versatile materials widely utilized in various industries for creating precision-cut items. These boards are especially prevalent in the production of paper goods such as toilet papers, napkins, and other disposable products. The adaptability of die cut KT boards makes them suitable for businesses ranging from hospitality to manufacturing plants and paper processing sectors.

Types and Applications

The applications of die cut KT boards are diverse, with machinery tailored for specific functions like stapling, folding, and embossing. These machines are integral in the production of paper cups, serviettes, and tissues. The type of die cut KT board selected can significantly impact the efficiency and output of these products, with options suitable for both small-scale and large-scale production needs.

Features and Technical Specifications

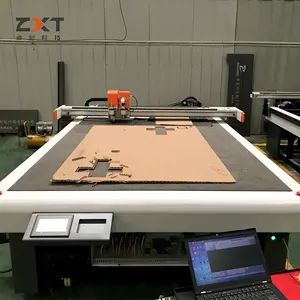

A typical die cut KT board machine may include advanced features such as embossing units with steel-to-steel or steel-to-rubber capabilities, offering a variety of pattern choices. Slitting, folding, and counting units are also standard, ensuring a streamlined production process. These machines are designed with either gear or chain driving systems and often boast full automation with automatic oil lubrication for consistent operation.

The technical prowess of these machines is evident in their use of photoelectric technology for monitoring operations and alerting to issues such as paper shortages or malfunctions. With varying weights and power usage, a smaller die cut KT board machine might use 3kw of power and handle 70 to 80 pcs/min, while larger machines can manage about 150m/min, equating to roughly 3 tons of product per day.

Materials and Construction

The construction of die cut KT boards is designed to withstand the demands of continuous operation. Most machines incorporate a robust air compressor pneumatic system and are controlled via a PLC control panel for enhanced automation. The choice of materials for these machines is critical to their durability and efficiency, ensuring they can meet the production demands of various industries.

Advantages of Using Die Cut KT Board Machines

Utilizing a die cut KT board machine in your production line can lead to increased efficiency and a higher quality of finished products. The automation of these machines reduces the need for manual labor and minimizes the risk of human error. Their precision in cutting and folding ensures a consistent product, which is essential for maintaining customer satisfaction and brand reputation.

Choosing the Right Die Cut KT Board

Selecting the appropriate die cut KT board machine is crucial for your business's operational efficiency and output quality. Factors such as production scale, desired patterns, and automation level should be considered to find a machine that aligns with your specific needs. While Alibaba.com does not manufacture these machines, the platform offers a vast selection from various Chinese wholesalers, allowing businesses to find the right fit for their production requirements.