Popular in your industry

Related Searches:

Top categories

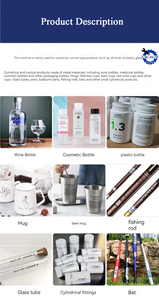

About cylinder printing machine

The Role of the Printing Cylinder Machine

At the heart of the printing sector, printing cylinder machines are pivotal for generating top-notch prints on diverse materials, including paper, textiles, and plastics. These apparatuses are engineered to secure printing plates that impart text, imagery, and other visual elements onto a selected medium. The caliber of the print output hinges on the precision and skill embodied in these cylinders.

Printing cylinder machines are employed by print shops, advertising firms, industrial manufacturers, and even for domestic purposes, such as crafting custom invitations or gift cards. They operate on offset printing tenets, whereby the image is initially transferred to a rubber blanket, then to the final medium. This indirect printing technique ensures uniform, high-quality results, particularly for extensive production batches.

The machine orchestrates a sequence of rollers and cylinders, each fulfilling a distinct function: the plate cylinder secures the printing plates, the impression cylinder applies pressure to the plates against the medium, and the doctor blade system, when present, modulates the ink volume deposited on the medium. Contemporary enhancements include automated print job management systems, meticulous engineering for exact registration, and versatile options for ink types and color setups.

Varieties of Printing Cylinder Machines

Printing cylinder machines are available in multiple forms, each tailored to specific printing requirements and substrates. Below are some prevalent models:

-

Flexographic Printing Cylinder Machine: Favoured for its rapid production and adaptability with various inks and substrates, this machine is a staple for packaging materials, printing efficiently on extended roll-to-roll mediums.

-

Gravure Printing Cylinder Machine: Celebrated for its superior image fidelity, gravure printing is the go-to for intricate graphics on labels and flexible packaging. Its direct-to-substrate method is advantageous for high-definition prints.

-

Offset Printing Cylinder Machine: A mainstay in commercial printing, this machine delivers exquisite print quality by transferring ink from a plate to a rubber blanket, then onto the print surface.

-

Letterpress Printing Cylinder Machine: Known for its direct impression technique, where the plate contacts the paper, letterpress is synonymous with high-end stationery and book printing that requires a tactile impression.

-

Screen Printing Cylinder Machine: Screen printing presses ink through a screen onto the substrate, making it ideal for textiles, signage, and promotional items that benefit from a distinctive texture.

Selecting a Printing Cylinder Machine

Choosing the appropriate Printing Cylinder Machine for your enterprise entails evaluating several factors to match your production requisites:

-

Printing Method: Ascertain the need for an inline or offline machine, contingent on your operational framework and volume requirements. Inline machines integrate printing with other processes like coating or drying, essential for some sectors.

-

Substrate Material: The substrate you plan to print on—whether paper, plastic, fabric, or metal—will dictate your machine selection. Certain machines are specialized for specific materials, while others are more versatile.

-

Printing Quality: Establish the quality benchmark you aspire to. For high-definition imagery with multiple color options, verify the machine's capability to deliver such standards.

-

Speed and Productivity: Gauge the machine's production capacity. High-speed units may be imperative for bulk runs, whereas specialized machines may offer unique features that boost productivity.

-

After-Sales Service: Opt for vendors that offer extensive after-sales support, including video technical assistance or on-site maintenance services, which are crucial for optimizing operational uptime.

Discover Printing Cylinder Machines on Alibaba.com

Alibaba.com emerges as a global marketplace aggregating an expansive array of printing cylinder machines from worldwide suppliers. The platform serves as an invaluable resource for businesses in search of dependable and proficient equipment to satisfy their operational demands. With a broad spectrum of choices that cater to various printing techniques and substrates, Alibaba.com streamlines the procurement of the ideal machine, whether for digital printing or bulk retail packaging production.

The site's user-friendly interface allows for effortless comparison of features such as color page capacity, component durability, automation level, and principal selling points. This granular data enables businesses to make well-informed choices that resonate with their unique needs, bypassing the need to engage multiple suppliers individually.

Furthermore, Alibaba.com's dedication to secure trading through offerings like Trade Assurance safeguards your investment until your machinery is fully operational. The platform's commitment to aiding small and medium-sized enterprises with online trade solutions solidifies its status as a reliable partner in international commerce. Opting for Alibaba.com for your printing cylinder machine needs signifies a partnership with a system tailored to streamline global trade and bolster your business's growth in the competitive industrial printing arena.

Frequently Asked Questions About Printing Cylinder Machines

What functions does a printing cylinder serve in the printing industry?

In various printing methodologies, such as offset, flexographic, and digital, a printing cylinder is instrumental in transferring images or text onto substrates like paper, cardboard, or labels.

How does a printing cylinder operate?

A printing cylinder functions by rotating at elevated speeds, applying ink to a printing plate or substrate, and then transferring the image to the receiving surface with assistance from a pressure roller.

What materials are commonly used to construct printing cylinders?

Printing cylinders are typically crafted from robust metals such as steel or aluminum, with a printing surface that is copper or chrome-plated to ensure smoothness and extend service life.

What are the different types of printing cylinders available?

Printing cylinders come in various forms, including those designed for flatbed, rotary, and cylinder printers, each suited to distinct printing methods and applications.

How can I ascertain the appropriate size and type of printing cylinder for my press?

The suitable size and type of printing cylinder for your press depend on the printing technique, the substrate to be printed, the press's specifications, and the desired quality of output.

Is it possible to customize printing cylinders for particular printing needs?

Indeed, suppliers frequently provide customization services for printing cylinders to accommodate specific printing demands or to integrate with particular printing apparatuses.

What criteria should I consider when selecting a printing cylinder supplier on Alibaba.com?

In selecting a supplier on Alibaba.com, evaluate their production capabilities, customization offerings, quality assurance practices, and the availability of after-sales support that may be required.

Are there varying grades of printing cylinders on offer?

Yes, suppliers may present different grades of printing cylinders, differentiated by aspects such as material quality, surface finishing, hardness, and precision.

What distinguishes an engraved from a laser-engraved printing cylinder?

An engraved cylinder features a design etched into its surface for inking and printing, whereas a laser-engraved cylinder employs laser technology to create raised designs that impart texture to the paper.

In what ways does the material of a printing cylinder impact its performance?

The material composition of a printing cylinder significantly influences its durability, print quality, and compatibility with inks or other printing substances.

What kind of after-sales services are typically provided with a printing cylinder purchase?

After-sales service offerings vary among suppliers but may encompass online support, video technical assistance, field maintenance and repair services, and access to engineers for overseas machinery servicing.

What measures can I take to prolong the life of my printing cylinder?

To extend the life of your printing cylinder, adhere to the maintenance guidelines issued by the manufacturer and consider factors such as the type of substrate you print on and the frequency of cylinder usage.