Exploring the Versatility of Collaborative Robots

Collaborative robots, or 'cobots', represent a revolutionary category in the realm of automation. These sophisticated machines are designed to work alongside human personnel, enhancing efficiency and safety within a multitude of industrial applications. Unlike traditional robots, cobots are built with advanced sensors and systems that allow them to interact safely with their human counterparts.

Types and Applications of Collaborative Robots

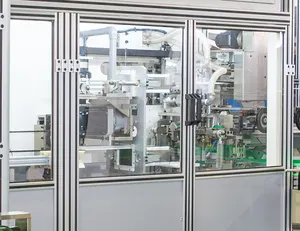

The types of collaborative robots vary, ranging from small tabletop models to larger units capable of lifting significant weight. Each type is tailored to specific tasks such as assembly, packaging, machine tending, and material handling. The adaptability of cobots makes them suitable for a wide array of industries, including automotive, electronics, pharmaceuticals, and food and beverage.

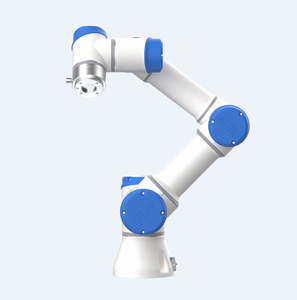

Features and Materials of Collaborative Robots

Collaborative robots are engineered with precision and are composed of high-grade materials that ensure durability and longevity. The features of these robots often include user-friendly interfaces, allowing for easy programming and operation. Their construction typically involves lightweight yet robust materials, facilitating easy movement and reconfiguration within various production environments.

Advantages of Implementing Collaborative Robots

The integration of a collaborative robot within a production line can significantly boost operational efficiency. These robots are designed to perform repetitive tasks with consistent accuracy, reducing the margin for error. Moreover, their deployment can lead to a safer workplace as they can take over hazardous tasks, thus minimizing the risk of injuries and allowing human workers to focus on more complex responsibilities.

Enhancing Productivity with Collaborative Robots

Incorporating collaborative robots into your workflow can transform productivity levels. Their ability to operate 24/7 without fatigue means that they can complement shifts, ensuring a continuous production cycle. This constant operation can lead to an increase in output, making a collaborative robot a valuable asset in meeting high demand.

Collaborative Robots: A Step Towards Future Automation

As industries move towards more advanced levels of automation, collaborative robots stand at the forefront of this evolution. Their ability to learn and adapt to new tasks through artificial intelligence and machine learning algorithms signifies a leap in industrial capabilities, paving the way for smarter, more responsive manufacturing environments.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4