Exploring the Versatility of Checking Fixtures

Checking fixtures are essential tools in manufacturing and quality assurance processes, ensuring that parts meet precise specifications. These fixtures are pivotal in verifying the dimensional integrity of components, particularly in sectors like automotive manufacturing, where an automotive checking fixture is crucial for maintaining the consistency of production lines.

Types and Applications of Checking Fixtures

The diversity of types of checking fixtures is vast, with each type serving a specific purpose. For instance, a runout checking fixture is designed to assess the runout, or the degree of wobble in a rotating part. Similarly, a concentricity checking fixture is used to ensure the central alignment of cylindrical parts. These fixtures are not limited to the automotive industry; they are also integral in aerospace, medical, and consumer electronics where precision is paramount.

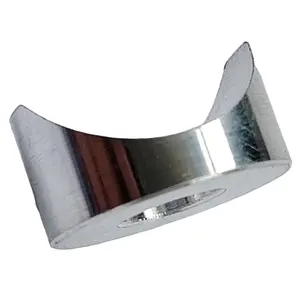

Features and Materials of Checking Fixtures

A checking fixture is characterized by its robust construction and material choice, which is often tailored to the application. Materials range from hardened metals for durability to composites for lightweight needs. The design of a jig checking fixture, for example, incorporates features that facilitate easy handling and accurate positioning of parts for inspection.

Advantages of Utilizing Checking Fixtures

The advantages of using checking fixtures in manufacturing are manifold. They significantly reduce the time needed for quality control, enhance repeatability, and minimize human error. The implementation of checking fixture standards ensures that these fixtures can be universally applied and trusted for their precision and reliability.

Innovations in Checking Fixture Technology

Innovation in this field has led to the development of the CF checking fixture, which stands for 'customizable fixture.' This type of fixture can be tailored to specific manufacturing needs, providing flexibility and adaptability. Advanced manufacturing techniques, such as EDM machining, which utilizes electrical sparks to shape materials, are also employed in the creation of these fixtures, enhancing their capabilities and the precision of the inspection process.

Conclusion

In conclusion, checking fixtures play a pivotal role in the manufacturing landscape, offering a range of solutions for quality assurance. From the automotive industry to electronics, these fixtures provide the necessary assurance that parts and components are produced within the required tolerances. While Alibaba.com serves as a platform to connect buyers with a multitude of suppliers offering these indispensable tools, it is the responsibility of each buyer to engage with suppliers to ensure that the selected checking fixtures meet their specific needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4