Popular in your industry

Related Searches:

Top categories

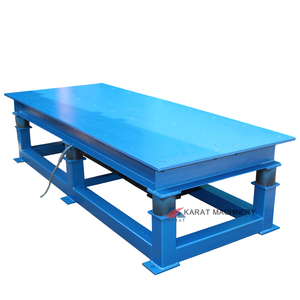

About cement mould vibrating table

Introduction to Cement Mould Vibrating Tables

Cement mould vibrating tables are essential tools in the construction and manufacturing industries, designed to enhance the quality and integrity of concrete structures. These specialized tables are engineered to consolidate concrete by emitting vibrations at various frequencies and intensities, ensuring a compact and void-free end product.

Types and Applications

There are several types of vibrating tables, each suited for specific scenarios and applications. Internal vibrators, or needle vibrators, are equipped with a long tube and a vibrating head, ideal for situations where direct contact with concrete is possible. External vibrators, or form vibrators, are used when internal methods are impractical, although they may lead to energy inefficiencies. Surface vibrators are best for concrete with an intensity of less than 20 cm. Across industries, from transportation to laboratory research, these tables play a pivotal role in ensuring the durability and reliability of concrete applications.

Features and Materials

A cement mould vibrating table typically comprises a robust metal platform mounted on steel springs, powered by an electric motor. The construction of these tables involves high-grade materials that withstand the rigorous process of compacting stiff concrete mixtures. The vibratory motion is carefully calibrated to eliminate air gaps and potential defects within the concrete, contributing to the overall quality of the finished product.

Advantages of Using Vibrating Tables

Utilizing a concrete compaction table ensures a smoother, more uniform surface, free from common defects such as bug holes and honeycombing. This process not only enhances the aesthetic appeal of the concrete but also significantly improves its structural integrity. By removing air gaps and potential points of weakness, these tables help in constructing safer buildings capable of withstanding natural forces like earthquakes and the rigors of daily wear and tear.

Selection Considerations

When selecting a concrete vibration table, it's crucial to consider the specific requirements of the task at hand. Factors such as the size of the table, the frequency of vibration, and the type of concrete mixture being compacted are all important. It's also essential to choose a table that is compatible with the work environment, whether it's for on-site construction needs or for precision work in a controlled laboratory setting.

Ensuring Quality in Construction

In conclusion, a vibrating table for concrete molds is a vital component in the construction process, ensuring that each structure is built to last. While the market offers a variety of options, it is important to select a table that meets the specific needs of your project, contributing to the longevity and safety of your concrete structures.