Introduction to Casting Moulding Machines

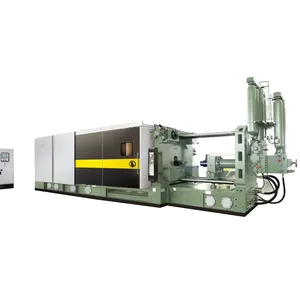

Casting moulding machines are pivotal in the manufacturing sector, serving as the backbone for metal shaping and forming. These machines facilitate the transformation of molten metal into predefined shapes through the use of dies and various impression devices. The versatility of casting moulding machine models ranges from handling different metals to accommodating various production scales, making them indispensable in industrial settings.

Types and Applications

The landscape of casting moulding machines encompasses a variety of types, each tailored for specific applications. Injection machine moulding units are renowned for their precision in producing complex parts, while aluminium injection moulding machines specialize in handling lightweight, yet sturdy aluminium parts. For larger components, sand moulding machines and green sand moulding machines are the go-to equipment, widely used in the automotive and heavy machinery industries. The automatic moulding machine for foundry operations streamlines production, enhancing efficiency and consistency.

Features and Materials

Modern casting moulding machines are engineered to meet diverse industrial demands. They are constructed from robust materials that withstand high temperatures and prolonged use. The intricate design of shell molding machines and rotational casting machines reflects advancements in technology, aiming to improve the precision and durability of the moulds. These machines cater to a range of metals, including iron and brass, as seen in iron moulding machines and brass moulding machines, which are tailored for specific metallurgical properties.

Advantages of Advanced Moulding Technology

The adoption of automatic plastic injection moulding machines and new injection moulding machines in the industry has revolutionized production lines, offering enhanced speed and product uniformity. The integration of automation reduces human error and increases throughput. Similarly, gold moulding machines have refined the art of precious metal moulding, providing the precision required for high-value items.

Choosing the Right Machine for Your Business

Selecting the appropriate casting moulding machine is crucial for optimizing production. Factors such as size, power, capacity, and specific metal compatibility must be considered. Suppliers on Alibaba.com offer a range of machines to suit various business needs, from cast iron moulding machines for heavy-duty applications to intricate gold moulding machines for the jewelry industry. It is essential to consult with suppliers to find the machinery that aligns with your operational requirements.

Connect with Trusted Suppliers

Alibaba.com serves as a gateway to connect with numerous suppliers of casting moulding machines and related machinery. The platform facilitates the discovery of equipment that embodies performance, sturdiness, and precise engineering without endorsing any specific brand. Businesses can engage with suppliers to inquire about machinery specifications and terms of sale, ensuring an informed investment decision.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4