Popular in your industry

Related Searches:

Top categories

About calcium carbonate manufacturing plant

Introduction to Calcium Carbonate Manufacturing Plants

Calcium carbonate manufacturing plants are industrial setups dedicated to the production of calcium carbonate, a fundamental compound used in various industries. These plants perform a series of processes to convert raw limestone or marble into a fine, purified calcium carbonate powder. The versatility of calcium carbonate makes these plants vital to sectors such as agriculture, pharmaceuticals, and construction.

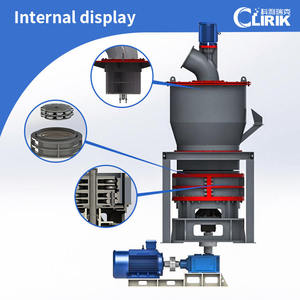

Types of Calcium Carbonate Processing Equipment

Within a calcium carbonate factory, different types of machinery are employed. Each piece of equipment is designed to handle specific stages of the manufacturing process, from crushing raw materials to milling them into a fine powder. The choice of equipment impacts the efficiency and quality of the final product.

Applications and Features

The produced calcium carbonate from these plants has a wide range of applications. It's a primary ingredient in cement and is used in the purification of iron. In the agricultural sector, it adjusts soil pH levels, while in the pharmaceutical industry, it's used as a calcium supplement or an antacid. The features of a calcium carbonate manufacturing plant are tailored to meet the stringent requirements of these diverse applications, ensuring consistency and purity of the product.

Materials and Advantages of Calcium Carbonate Production

The raw materials used in a calcium carbonate manufacturing plant are typically sourced from quarries rich in limestone or marble. The advantages of using high-grade raw materials include a superior end product with high brightness and minimal impurities. Advanced milling technology in the plant ensures efficient processing, resulting in fine-grade calcium carbonate with optimal particle size distribution.

Choosing the Right Calcium Carbonate Manufacturing Equipment

Selecting the appropriate machinery for a calcium carbonate factory is crucial. Factors to consider include the plant's production capacity, the quality of the end product, and the machinery's energy consumption. A well-equipped plant will leverage advanced milling and processing technologies to maximize output while minimizing energy use.

Environmental Impact and Sustainability

Modern calcium carbonate manufacturing plants are designed with sustainability in mind. They aim to reduce waste and incorporate recycling in the production process. Efficient dust collection systems and waste treatment protocols are in place to minimize the environmental footprint of the manufacturing process.