Exploring CAD CAM Machine Wood Capabilities

The realm of woodworking has been revolutionized by the advent of CAD CAM machine wood technology. These sophisticated machines bring precision and efficiency to the production process, catering to both small-scale artisans and large-scale manufacturing operations. The integration of Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) allows for intricate designs to be flawlessly executed on a variety of wood materials.

Types and Applications of Woodworking CAD CAM Solutions

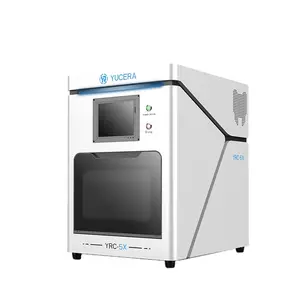

Diverse in their applications, CAD CAM machines for wood are indispensable in industries ranging from furniture making to architectural modeling. Users can select from an array of machine types such as routers, lathes, and millers, each serving specific functions from shaping to detailed carving. The versatility of these machines means they are not just limited to cutting and engraving but are also capable of complex tasks like 3D modeling and sculpting.

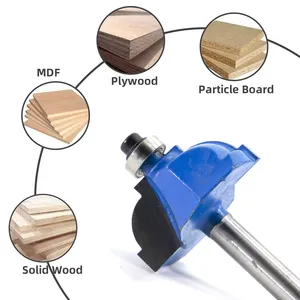

Features and Materials Compatibility

The efficacy of a woodworking CAD CAM machine lies in its features which include high-speed machining, exceptional accuracy, and the ability to handle various wood densities. These machines are compatible with a wide range of wood materials, from softwoods to hardwoods, as well as composite materials, ensuring they meet the diverse needs of the woodworking sector.

Advantages of Utilizing CAD CAM Technology in Woodworking

Employing CAD CAM technology in woodworking brings numerous advantages. It significantly reduces waste by optimizing cutting paths, enhances the consistency of finished products, and accelerates production times. Moreover, it minimizes the reliance on manual labor, thereby reducing the potential for human error and ensuring repeatability in mass production scenarios.

Considerations for Selecting the Right Machine

When considering a CAD CAM wood machine, it is crucial to assess the specific needs of your operation. Factors such as the machine's compatibility with different wood types, its precision capabilities, and the size of the wood it can accommodate should influence the decision-making process. Prospective buyers should thoroughly evaluate the range of machines available to ensure the selected equipment aligns with their production requirements.

Maintaining Your CAD CAM Woodworking Machine

To maximize the lifespan and efficiency of a CAD CAM woodworking machine, regular maintenance is essential. This includes routine cleaning and the timely replacement of worn components. Proper upkeep not only extends the machine's operational life but also ensures consistent quality in production outputs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4