Introduction to Bullet Making Machines Lead

The realm of ammunition manufacturing is intricate, with bullet making machines lead playing a pivotal role in the production process. These machines are engineered to shape lead and other metals into precise bullet forms, catering to the diverse needs of the ammunition industry. The versatility of these machines allows for the creation of various bullet types, each designed to meet specific standards and applications.

Types and Applications

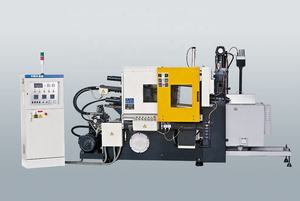

Lead bullet casting machines come in several types, each serving a unique function in bullet production. From die casting machines that offer meticulous shape conformity to continuous casting machines designed for efficient mass production, the range is extensive. The applications of these machines span from small-scale bespoke bullet crafting to large-scale ammunition manufacturing, demonstrating their adaptability to different production volumes and requirements.

Features and Materials

The construction of bullet making machines lead involves robust materials capable of withstanding high temperatures and pressures. Features such as advanced temperature control and precision molds are integral to the performance of lead bullet casting equipment. These features ensure that each bullet is cast with uniformity and to exact specifications, which is crucial in the ammunition industry.

Advantages of Modern Casting Machines

Modern bullet making machines lead boast enhanced efficiency and reliability. The integration of cutting-edge technology in vacuum casting machines and centrifugal casting machines has elevated the standards of bullet production, resulting in consistent output and reduced waste. The adaptability of these machines to different lead grades and specifications makes them a valuable asset in the field of bullet manufacturing.

Accessories and Customization

In addition to the primary machinery, a range of bullet casting machine parts is available to customize and upgrade the equipment. These parts are designed to fit various machine models and enhance their capabilities. Whether it's for replacing worn components or upgrading to handle different metal types, the availability of specific parts ensures that bullet making machines can be tailored to a manufacturer's unique needs.

Choosing the Right Machine

Selecting the appropriate bullet making machines lead is crucial for any business in the ammunition sector. Alibaba.com serves as a marketplace where suppliers offer a multitude of options, from new bullet casting machines to pre-owned models, each with detailed specifications. Prospective buyers can connect with suppliers to find the equipment that aligns with their production requirements and technical preferences.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4