Bottle Pressure Tester: An Essential Tool for Quality Assurance

The bottle pressure tester is an indispensable instrument in the packaging and beverage industries, designed to assess the integrity and strength of various bottle types. This category of testing equipment is crucial for ensuring that bottles can withstand the pressure they will encounter during filling, capping, and transportation.

Understanding the Types and Applications

There are several types of bottle pressure testers available, each tailored to specific testing requirements. Some are designed for use with plastic PET bottles, while others are suitable for glass or even metal containers. The applications of these testers are diverse, ranging from carbonated beverage bottles to pharmaceutical containers, ensuring they meet safety and quality standards.

Features and Materials

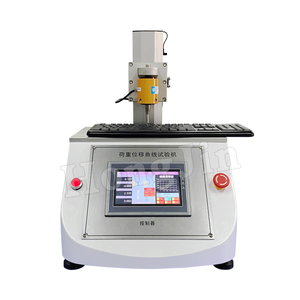

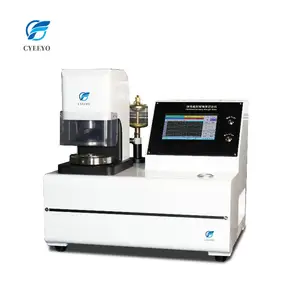

A typical bottle pressure tester is equipped with features that allow for accurate measurement of the pressure resistance of bottles. These may include digital readouts, adjustable pressure settings, and automatic detection systems. The materials used in the construction of these testers are often robust, such as stainless steel, to withstand the rigors of repeated use and to ensure longevity and consistent performance.

Advantages of Utilizing Bottle Pressure Testers

Employing a bottle pressure tester in quality control processes offers numerous advantages. It ensures compliance with industry standards, reduces the risk of product recalls, and enhances consumer safety. Moreover, it aids in the optimization of bottle design by providing data on how to improve bottle strength without unnecessary use of materials.

Selection Criteria for Bottle Pressure Testers

When selecting a bottle pressure tester, it is important to consider the specific needs of the task at hand. Factors such as the range of pressure it can test, compatibility with different bottle sizes and shapes, and the precision of the measurements are all critical considerations. Additionally, ease of use and maintenance are important for efficient operation.

Complementary Tools for Comprehensive Testing

For a complete testing suite, one might consider integrating other instruments alongside the bottle pressure tester. Devices such as torque testers, which measure the force required to open a bottle cap, and vacuum leak testers, which detect leaks in a bottle's seal, can provide a more thorough analysis of a bottle's overall quality and safety.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4