Introduction to Belt Conveyor Rollers

Belt conveyor rollers are integral components of material handling systems, designed to facilitate the smooth and efficient movement of goods across various industrial sectors. These rollers support and move conveyor belts, which carry loads from one point to another, making them essential in the automation of production lines and logistics operations.

Types and Applications

The versatility of belt conveyor rollers is evident in their range of types and applications. From lightweight to heavy-duty tasks, these rollers are tailored to meet diverse operational needs. They are commonly used in sectors such as mining, agriculture, automotive, and packaging. Specific types include gravity rollers, which rely on inclination and gravity for movement, and motorized rollers that are powered to handle heavier loads.

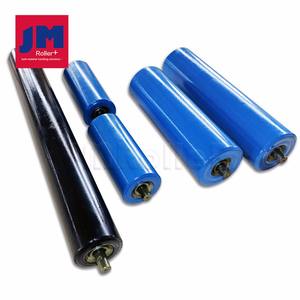

Features and Materials

Conveyor idlers and rollers are crafted from various materials, each selected for durability and functionality. Common materials include steel, which offers strength for heavy loads, and plastic or rubber for quieter and lighter operations. The design of these rollers may include features such as sealed bearings to prevent contamination and extend the roller's lifespan.

Advantages of Using Quality Rollers

Utilizing well-constructed conveyor belt parts such as rollers can significantly enhance operational efficiency. They reduce the manual labor required to move products, minimize the risk of workplace injuries, and can be customized to fit specific conveyor systems. Additionally, the right selection of rollers can lead to improved load-bearing capacity and reduced maintenance costs.

Complementary Components

In addition to rollers, a conveyor system comprises various other parts. Roller skate wheel conveyors and elevator buckets are examples of components that work in conjunction with rollers to optimize the transportation of materials. While roller drums are used to drive the belt, maintaining tension and alignment, steel bearing wheels ensure the smooth rotation of the rollers.

Choosing the Right Belt Conveyor Roller

Selecting the appropriate belt conveyor roller is crucial for the efficiency and longevity of the conveyor system. Factors to consider include the size and weight of the materials being transported, the environment in which the system operates, and the desired speed of the belt. It is important to consult with a knowledgeable supplier who can provide guidance on the best roller type for your specific needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4