Introduction to Automatic Cone Winding Machines

The realm of motor repairs and electrical appliance manufacturing is witnessing a transformative shift with the integration of automatic cone winding machines. These sophisticated devices are engineered to streamline the process of coil rewinding, thereby enhancing productivity and efficiency in workshops and factories. This category encompasses a range of machines designed to automate the winding of coils used in various electrical components, such as solenoids and transformers.

Types and Applications

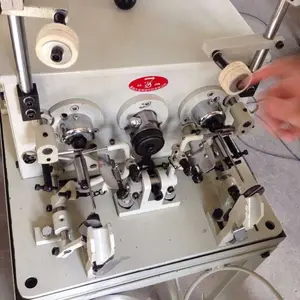

Within the industry, there are several types of winding machines, each serving a specific purpose. From autonomous winding machines that operate with minimal human intervention to semi-automatic electrical machines that combine automation with manual control, the spectrum is broad. The applications of these machines are equally diverse, catering to commercial, industrial, and even small-scale operations. They are pivotal in the production of electrical fans, transformers, and other appliances requiring precise coil winding.

Features and Materials

An automatic cone winding machine is not just about automation; it's about precision and durability as well. These machines are constructed from robust materials that withstand the demands of continuous operation. Features may include user-friendly interfaces, adjustable settings for various coil sizes, and consistent performance. The design of these machines focuses on delivering precision in winding tasks, ensuring that each coil is perfectly formed for optimal electrical function.

Advantages of Automation in Winding

The transition to automation through the use of an automatic cone winding machine offers numerous advantages. Efficiency is significantly increased as these machines can produce more coils in less time compared to manual winding. The requirement for labor is reduced as well, often to a single operator for certain models. Furthermore, the consistency and precision provided by these machines can contribute to the longevity and reliability of the electrical appliances they help create.

Maintenance and Operation

Ease of maintenance is a key feature of a modern automatic cone winding machine. With designs that are focused on long-term use, these machines require minimal upkeep. Operational guidelines and instructions are typically provided to ensure proper handling and care. For businesses looking to incorporate these machines, understanding their operation is made simpler with available demonstrations, often facilitated by skilled technicians.

Choosing the Right Machine

Selecting the appropriate automatic cone winding machine is crucial for meeting specific production needs. Alibaba.com hosts a wide array of machines, each vetted to meet various international production standards. While the platform facilitates the connection between buyers and suppliers, it is essential for buyers to assess the machines' capabilities and ensure they align with their operational requirements. The platform's inventory includes machines that cater to different scales of operation, from large industrial setups to smaller, cottage industry environments.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4