Popular in your industry

Related Searches:

Top categories

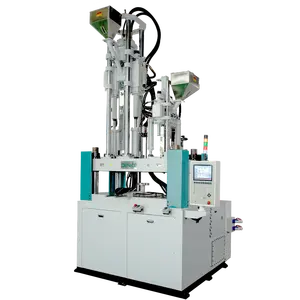

About aluminium injection molding machine

Aluminum is an extremely versatile material, and the use of an aluminium injection molding machine allows its properties to be leveraged in various industries for the production of complex and precise parts. The aluminum injection molding process offers a range of benefits, including improved design capabilities, reduced material waste, and the ability to create lightweight and corrosion-resistant components. The aluminum injection molding machine uses high pressure to inject molten aluminum into a mold cavity, where it solidifies to form the desired part. This process is highly repeatable and can be automated, making it a cost-effective solution for large-scale production. Additionally, the thermal conductivity of aluminum allows for faster cycle times, further enhancing efficiency. The aluminum injection molding machine is a valuable tool for manufacturers looking to create high-quality aluminum parts with intricate designs and tight tolerances.

The benefits of using an aluminum injection molding machine

Aluminum injection molding offers several advantages, including the ability to produce complex and lightweight parts. The use of an aluminum injection molding machine allows for the creation of intricate designs with thin walls and complex geometries, making it suitable for applications where weight reduction is crucial. The process also enables the production of parts with excellent dimensional accuracy and surface finish, reducing the need for secondary operations. Furthermore, aluminum injection molding is a cost-effective solution, as it minimizes material waste and allows for high-volume production. The aluminum injection molding machine is highly efficient, with fast cycle times and the ability to incorporate multiple features into a single part. Additionally, the corrosion resistance of aluminum makes it suitable for a wide range of industries, including automotive, aerospace, and electronics.

The application of aluminum injection molding

The aluminum injection molding process finds applications in various industries, ranging from automotive and aerospace to consumer electronics and medical devices. In the automotive sector, aluminum injection molding is used to produce lightweight components that enhance fuel efficiency and reduce emissions. These components include structural parts, heat sinks, and engine components. The aerospace industry leverages aluminum injection molding to create complex and lightweight parts for aircraft and spacecraft. These parts are designed to withstand extreme conditions while minimizing overall weight, contributing to improved performance and fuel efficiency. In the consumer electronics industry, aluminum injection molding is used to manufacture housing components for devices such as smartphones, laptops, and wearables. The process allows for the integration of features like heat dissipation, EMI shielding, and intricate designs in a single part, enhancing the overall functionality and aesthetics of the products. Additionally, the medical sector utilizes aluminum injection molding to produce components for devices and equipment. The corrosion-resistant properties of aluminum make it suitable for applications requiring sterilization, such as surgical instruments, diagnostic devices, and drug delivery systems.

Aluminum injection molding, a critical process in the manufacturing industry, offers many advantages in the production of complex and lightweight parts. It involves injecting molten aluminum into a mold cavity to create intricate designs with thin walls and complex geometries. The process is cost-effective and minimizes material waste, making it suitable for high-volume production. Aluminum injection molding is widely used in industries such as automotive, aerospace, electronics, and medical devices, where the properties of aluminum, including corrosion resistance and thermal conductivity, are highly valued.