Popular in your industry

Related Searches:

Top categories

About aluminium fabrication materials

Understanding Aluminum Fabrication Supplies

Aluminum fabrication supplies include a broad array of materials and tools necessary for constructing aluminum frameworks, components, and products. These supplies are indispensable for sectors that leverage aluminum's advantageous traits, such as its lightness, superior strength-to-weight ratio, and resistance to corrosion. Aluminum fabrication is a multi-step process that entails cutting, bending, welding, and occasionally, applying surface treatments to attain the required form, dimensions, and properties.

Entities engaged in industries like construction, automotive, aerospace, electronics, and more frequently depend on these supplies. Grasping the fundamentals of aluminum fabrication requires knowledge of the material's characteristics, its physical properties, and the methods available for its manipulation. For example, slicing through aluminum sheets might involve high-velocity saws or laser cutters, while bending could necessitate the use of press brakes or roll benders. Similarly, the assembly of aluminum parts might involve welding techniques or adhesives.

The efficacy of aluminum fabrication is contingent upon the expertise of the professionals and the caliber of the equipment at their disposal. Through a synergy of seasoned proficiency and advanced technology, these suppliers can deliver a plethora of bespoke aluminum solutions that conform to precise specifications and quality benchmarks.

Varieties of Aluminum Fabrication Supplies

Aluminum fabrication supplies are available in diverse forms to cater to particular demands within the industry. Below are some prevalent types:

-

Aluminum Sheets and Plates: These flat pieces of aluminum serve as foundational materials for a multitude of products. Available in various grades and thicknesses, they are utilized in applications ranging from aircraft production to signage creation.

-

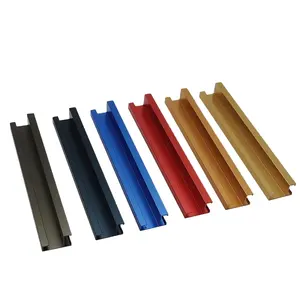

Aluminum Extrusions: Produced by pushing the metal through a die, these shapes, such as angles, channels, or tubes, are integral to the construction of solar panel frames and components in the building and automotive sectors.

-

Aluminum Composite Panels (ACP): Comprising two slender aluminum sheets with a core layer sandwiched between them, ACPs are favored for their lightness in building facades and signboards.

-

Aluminum Foil: Essential in both domestic and commercial settings, aluminum foil is employed for food packaging, insulation, and even in scientific research.

-

Aluminum Coils: These elongated strips of aluminum are coiled into rolls and are commonly used as starting material for applications such as guttering or in HVAC systems.

Selecting Aluminum Fabrication Supplies

Choosing appropriate aluminum fabrication supplies involves careful deliberation of various aspects:

-

Type of Fabrication: The intended shaping method for the aluminum (e.g., extrusion, rolling, casting) should guide your supply selection. Each technique has unique benefits that may align with the needs of your project.

-

Alloy Selection: The alloy chosen will influence the material's strength, longevity, and malleability. For instance, 6000-series aluminum alloys are known for their optimal balance of strength and corrosion resistance, making them apt for structural uses, while 5000-series alloys are exceedingly pliable, ideal for electrical uses.

-

Form: The form in which aluminum is supplied (e.g., sheets, foils, rods) should match the requirements of your project. For insulation purposes, particularly in electrical applications, select a form that is conducive to this use.

-

Finish: The finish (e.g., mill finish, anodized) can impact both the aesthetic and functional aspects. Opt for a finish that satisfies your project's visual expectations and provides the necessary defense against environmental factors.

By weighing these elements against the extensive offerings on Alibaba.com's marketplace, businesses can pinpoint suppliers that fulfill their specific demands in terms of quality, volume, and customization capabilities.

Aluminum Fabrication Supplies on Alibaba.com

Alibaba.com distinguishes itself as a leading online marketplace that bridges businesses with an extensive network of suppliers providing premium aluminum fabrication supplies. With a wide selection designed to meet the varied requirements of global industries, Alibaba.com streamlines the procurement process for companies in search of dependable materials for their production endeavors. The platform's dedication to nurturing international trade connections ensures that businesses can procure high-caliber aluminum fabrications with assurance.

Alibaba.com eases global trade by offering tools that facilitate communication with suppliers in the buyer's native language and by managing order processing effortlessly, even on mobile devices. This commitment to simplifying business transactions positions Alibaba.com as the go-to source for wholesale aluminum fabrication supplies.

Furthermore, Alibaba.com's Trade Assurance program provides an additional safeguard by securing payments until delivery confirmation. This protection is vital for businesses placing large orders or requiring intricate custom fabrications. With a comprehensive suite of features and services designed to assist small and medium-sized enterprises at every growth stage, Alibaba.com stands as an essential partner for firms looking to efficiently acquire top-quality aluminum fabrication supplies while mitigating the risks of international commerce.

Frequently Asked Questions About Aluminum Fabrication Supplies

What is the primary benefit of using aluminum in fabrications?

Aluminum's principal benefit lies in its combination of lightness and strength, making it an ideal choice for fabrications that demand both robustness and reduced weight. It also boasts excellent corrosion resistance and tolerates a variety of environmental conditions well.

Is it possible to weld aluminum fabrications?

Certainly, aluminum fabrications can be welded using various techniques, including MIG, TIG, and Oxy-acetylene welding. The chosen method will depend on the aluminum type and material thickness.

Do aluminum fabrications come in different grades?

Indeed, aluminum is available in multiple grades that provide different levels of strength, ductility, and corrosion resistance. These grades are typically identified by a series of numbers and letters, such as 3003, 6061, and 7075.

Which fabrication processes are commonly applied to aluminum materials?

Aluminum materials are frequently shaped through processes like rolling for sheets and extrusion for profiles, as well as forging, stamping, and casting for more intricate forms. CNC machining is also employed for precision tasks.

How does alloy choice influence the performance of aluminum fabrications?

The selection of an alloy for aluminum fabrications dictates their performance attributes, such as the strength-to-weight ratio, corrosion resistance, and workability. It is crucial to choose an alloy that matches the specific needs of your application.

What considerations are important when selecting aluminum thickness for a project?

In choosing the thickness of aluminum for a project, it's important to consider structural integrity, durability needs, and weight limitations. Thicker aluminum typically offers greater strength and is more appropriate for heavy-duty applications.

What special considerations apply to aluminum fabrications in marine environments?

In marine settings, it is essential to use marine-grade aluminum alloy that exhibits high corrosion resistance to ensure longevity and functionality. Additional protective measures, such as anodized or coated finishes, can offer extra defense against the rigors of marine conditions.

How can I preserve the appearance of aluminum fabrications over time?

To maintain the aesthetic of aluminum fabrications, periodic cleaning with suitable aluminum cleaners is advisable. Refrain from using abrasive chemicals that could harm the material's surface or coating.

Can aluminum fabrications be tailored to my business's specific needs?

Yes, numerous suppliers provide customization services for aluminum fabrications to meet particular business needs, including adjustments in size, choice of material, and additional functionalities.

Which industries frequently employ aluminum fabrications?

Aluminum fabrications are extensively utilized in industries such as aerospace, automotive, construction, and consumer goods manufacturing, where the combination of lightness and strength is paramount.

How should I determine the appropriate type of finish for my aluminum fabrications?

When selecting a finish for aluminum fabrications, base your decision on the application's specific requirements. Finishes can range from protective layers like anodizing to decorative options such as powder coating or spray painting.

What is anodizing and how does it improve the look of aluminum fabrications?

Anodizing is an electrochemical procedure that forms a durable oxide layer on the surface of aluminum, enhancing its resilience and providing a more attractive finish. This process can be performed in various hues and offers additional corrosion protection.

Is there a standard specification for aluminum fabrications that I should be aware of?

While there is no single standard specification that applies to all aluminum fabrications, certain industry-specific standards may be relevant. Familiarizing yourself with the standards pertinent to your sector is important for ensuring regulatory adherence and consistent quality.

How is pricing determined for custom aluminum fabrications?

Custom aluminum fabrications are generally priced based on design complexity, material grade, finishing processes, and order volume. Prices may also fluctuate with market conditions and supplier pricing strategies.