Popular in your industry

Related Searches:

Top categories

About alcohol fermentation machine

Understanding Alcohol Fermentation Machines

Alcohol fermentation machines are specialized equipment used in the process of converting sugars into alcohol and carbon dioxide through the action of yeast. This process is fundamental in the production of various alcoholic beverages, including beer, wine, and spirits. The machinery involved in this process is designed to create optimal conditions for fermentation, ensuring consistency and quality in the final product.

Types of Fermentation Equipment

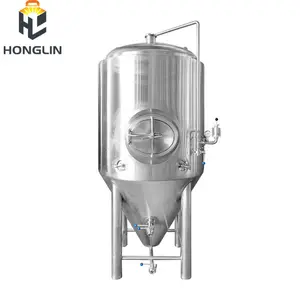

Diverse types of alcohol fermentation equipment cater to different scales of production and types of beverages. From commercial fermentation tanks to microbrewery fermenters, the range is extensive. Each type of machine is tailored to specific fermentation processes, such as aerobic or anaerobic fermentation, and is constructed to handle the particular requirements of the beverage being produced.

Features and Applications

Key features of an industrial fermentation machine include temperature control systems, agitation capabilities, and pressure adjustment functions. These features are crucial for managing the fermentation process, which can vary depending on the type of alcohol being produced. For instance, wine fermentation tanks are often equipped with cooling jackets to maintain the precise temperatures needed for wine's delicate fermentation process.

Materials and Construction

The construction materials of an alcohol fermentation machine are selected for durability and compatibility with the fermentation process. Stainless steel is a common choice due to its resistance to corrosion and ease of cleaning, which is essential for maintaining the purity and taste of the alcoholic beverage.

Advantages of Modern Fermenters

Modern beer fermentation systems offer numerous advantages, including improved control over the fermentation process, which can lead to a more consistent and higher quality product. Additionally, the use of advanced materials and design can enhance the efficiency of the fermentation process, potentially reducing production costs and time.

Choosing the Right Equipment

Selecting the appropriate distillery fermentation tank involves considering the scale of production, the specific type of alcohol being produced, and the desired features. It is important to evaluate the capacity, material, and technological aspects of the equipment to ensure it meets the needs of the production process.