Popular in your industry

Related Searches:

Top categories

About 80 ton forging press

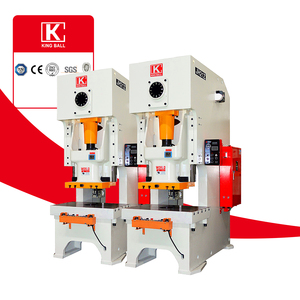

Introduction to the 80 Ton Forging Press

The 80 ton forging press represents a specific category of industrial machinery designed for metal shaping and forming. This type of press utilizes a substantial force, up to 80 tons, to manipulate metal into desired shapes through the forging process. The applications of such presses are diverse, ranging from the creation of small components to the manufacture of large-scale industrial parts.

Types of 80 Ton Forging Machines

Forging presses come in various configurations, each suited to particular tasks. The horizontal forging press is known for its horizontal movement during operation, primarily used for finishing and pre-forming of bar stock. Its mechanism involves a crank gear system that works in tandem with a camshaft to activate auxiliary parts. In contrast, the vertical forging press operates with a vertical tool movement, making it suitable for smaller forgings such as hooks and tool blanks. Lastly, rotary forging machines, which can also come in the 80-ton capacity, are utilized for hot drawing and swaging, featuring a unique rotational movement to shape metals.

Applications and Features

The 80 ton forging press is adept at handling a variety of metals, including steel, aluminum, and brass. Its robust construction allows for the production of a wide range of items, from automotive parts to hand tools. The versatility of this machinery lies in its ability to perform under intense conditions, ensuring consistent output for various forging applications. Features such as a high production rate and efficiency in metal deformation are intrinsic to this category of forging presses.

Materials and Construction

Constructed from durable materials, the 80 ton forging press is built to withstand the rigors of the forging process. The materials used in the construction of these machines are selected for their strength and ability to endure the stress of repeated use. This ensures a long operational life and reliability in the production environment.

Advantages of Using an 80 Ton Forging Press

An 80 ton forging press offers several advantages, including enhanced production efficiency and the capability to produce complex shapes with precision. The significant force exerted by the press translates to less time required to shape the metal, leading to faster production times. Additionally, the precision of these machines allows for reduced waste and higher consistency in the quality of the forged parts.

Choosing the Right Forging Press

Selecting the appropriate 80 ton forging press involves considering the specific requirements of the forging tasks at hand. Factors such as the type of metal, the complexity of the shapes to be forged, and the production volume should guide the selection process. With a range of machines available, it is possible to find a press that aligns with the operational needs of a business.