Popular in your industry

Top categories

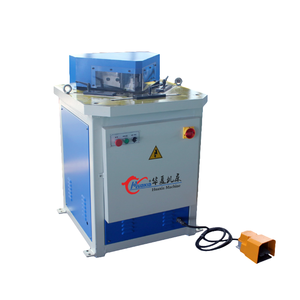

About 45 degree notcher

Introduction to 45 Degree Notchers

A 45 degree notcher is an essential tool in metalworking, designed to create precise notches at a 45-degree angle. This equipment is pivotal for tasks that require the joining of two tubes or the bending of metal pieces with accuracy. The notcher functions by cutting into the material, facilitating various manufacturing and construction processes.

Types of 45 Degree Notchers

The market offers a diverse range of notchers, including 45 degree hand notchers and their mechanized counterparts. Hand notchers are manually operated and are ideal for smaller projects or where precision is paramount. On the other hand, mechanized notchers come in several forms, such as pedal-operated, pneumatic, and hydraulic systems. Pedal notchers are known for their durability and energy efficiency, while pneumatic notchers are appreciated for their lightweight design and suitability for cutting metal box corners. Hydraulic notchers are prevalent in heavy-duty industrial applications due to their robustness and hydraulic transmission capabilities.

Applications and Industries

The versatility of a 45 degree notcher extends across various industries. They are indispensable in sectors such as boating, where precision joins are crucial, or in the manufacture of cooking utensils and automotive components. Their use is also widespread in the production of pipes, elevators, and stainless steel products, showcasing the notcher's adaptability to different materials and application requirements.

Features of 45 Degree Notchers

Notchers can be categorized into fixed and adjustable types based on the blade angle. Fixed angle notchers typically operate with a non-variable shear angle, often set at 90 degrees, and feature automatic blade gap adjustments in response to material thickness. Adjustable angle notchers offer flexibility, allowing the operator to change the blade angle as needed, which is particularly useful in custom fabrication settings.

Materials and Advantages

The construction of 45 degree notchers often involves high-strength materials such as silicon steel blades, ensuring durability and longevity. The design of these machines prioritizes operational efficiency, with features like centralized lubrication systems in fixed angle models, enhancing maintenance ease and machine performance.

Choosing the Right 45 Degree Notcher

Selecting the appropriate 45 degree notcher requires consideration of the specific industry needs and material types. While the hand notcher offers simplicity and control, hydraulic and pneumatic machines provide increased power and speed for larger scale operations. It is essential to assess the workpiece material, desired notch precision, and production volume when choosing the most suitable notcher for your tasks.