Introduction to Plastic Crushing Machines

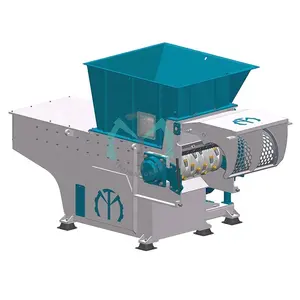

The realm of recycling is incomplete without the mention of plastic granulators. Central to this domain is the 40hp plastic crushing machine, a robust apparatus designed for the efficient breakdown of plastic materials into smaller, recyclable fragments. This category of machinery is pivotal for businesses aiming to enhance their recycling efficiency and contribute to environmental sustainability.

Types and Applications

Industrial plastic crushers come in various models to cater to different recycling needs. From single-shaft designs ideal for unique applications to versatile double-shaft models for higher volume processing, these machines serve a broad spectrum of crushing tasks. Their applications range from reducing PET bottles and PVC pipes to shredding polystyrene and other recyclable plastics, preparing them for the reprocessing stage.

Features and Efficiency

A 40hp plastic shredder is equipped with a potent motor and a suite of cutting blades, meticulously engineered to reduce plastic waste to the desired size. The efficiency of these machines lies in their ability to transform bulky plastic items into fine particles, which are then ready to be channeled into the production of new materials, thus closing the loop in the production cycle.

Materials and Advantages

Constructed to withstand the rigors of plastic crushing, these machines are made from durable materials that promise longevity and consistent performance. The advantages of integrating a heavy-duty plastic crusher into your recycling process include streamlining operations, reducing waste volume, and contributing to environmental conservation efforts.

Choosing the Right Machine

Selecting the appropriate plastic recycling equipment is crucial for achieving optimal recycling outcomes. Factors to consider include the type of plastic material for recycling, the volume of material to be processed, and the desired end-product size. With a comprehensive selection available, finding a machine that aligns with specific recycling requirements is straightforward.

Environmental Impact and Sustainability

The use of a plastic bottle crusher not only supports recycling initiatives but also plays a significant role in reducing the carbon footprint associated with plastic waste. By converting waste into reusable materials, these machines foster a more sustainable production model and contribute to the well-being of our planet.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4