Popular in your industry

Related Searches:

Top categories

About 3d wood cutter

Introduction to 3D Wood Cutters

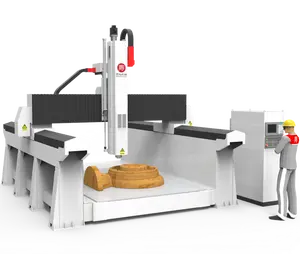

3D wood cutters are advanced machinery used for precision cutting and carving of wood materials. These machines utilize innovative technology to create intricate designs and shapes on wooden surfaces with high accuracy and efficiency. The primary keyword, 3d wood cutter, encompasses a range of equipment designed for various woodworking applications, making them essential tools for industries such as furniture manufacturing, cabinetry, and woodworking craftsmanship.

Technical Specifications

When considering 3d wood cutters, it's crucial to review the technical specifications to ensure they meet your specific requirements. These machines typically feature high-powered spindles ranging from 3 to 15 horsepower, allowing for precise cutting at varying speeds. The cutting area can vary from small desktop models suitable for hobbyists to large industrial machines with cutting dimensions exceeding 4 feet in length and width. Additionally, advanced models may offer multi-axis cutting capabilities for intricate 3D designs.

Features of 3D Wood Cutters

The 3d wood cutter machines come equipped with a plethora of features that enhance their performance and versatility. These include automatic tool changers that allow for seamless transitions between different cutting bits, dust collection systems to maintain a clean working environment, and CNC control systems for precise operation. Some models also offer laser cutting attachments for additional cutting options and capabilities.

Advantages of Using 3D Wood Cutters

Utilizing 3d wood cutters in woodworking processes provides several advantages. These machines enable faster production times compared to traditional manual methods, resulting in increased efficiency and productivity. The precision and accuracy of cuts achieved by 3D wood cutters ensure consistency in the final products, reducing material waste and enhancing overall quality. Furthermore, the ability to create complex 3D designs opens up new possibilities for creative woodworking projects.

Choosing the Right 3D Wood Cutter

When selecting a 3d wood cutter for your business, consider factors such as the intended use, cutting capacity, and budget constraints. Evaluate the machine's cutting area to ensure it can accommodate your typical project sizes and complexity. Additionally, assess the spindle power and cutting speed to match the requirements of your woodworking tasks. It's also essential to review the software compatibility and ease of use to streamline your production processes.

Applications of 3D Wood Cutters

The versatility of 3d wood cutters makes them suitable for a wide range of applications within the woodworking industry. These machines are commonly used for crafting custom furniture pieces, intricate wood carvings, decorative moldings, and architectural details. In addition to traditional woodworking, 3D wood cutters are utilized in industries such as sign making, prototyping, and model making for their precision cutting capabilities.

Maintenance of 3D Wood Cutters

To ensure optimal performance and longevity of 3d wood cutters, regular maintenance is essential. This includes routine cleaning of the machine to remove dust and debris that can affect cutting accuracy and spindle performance. Lubricating moving parts and checking for any signs of wear or damage are also crucial steps in preventing downtime and extending the machine's lifespan. Additionally, following manufacturer recommendations for maintenance schedules and inspections can help avoid costly repairs in the future.