Popular in your industry

Related Searches:

Top categories

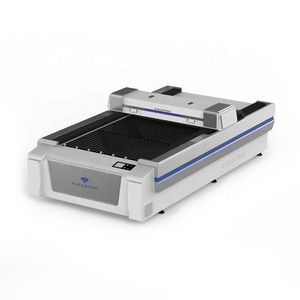

About 1626 laser cutting machine

Laser Cutting Technology Overview

Laser cutting stands as a transformative approach to material processing, where precision and efficiency are paramount. The 1626 laser cutting machine represents a class of equipment designed for intricate cutting tasks across various materials such as metals, woods, and fabrics. This technology has revolutionized industries by offering a non-contact cutting solution that minimizes contamination and the need for physical work holding.

Understanding the 1626 Laser Cutter

The 1626 laser cutter is engineered for versatility, catering to different scales of operation. Its design accommodates a range of materials, ensuring a seamless transition between tasks. Users should consider the machine's compatibility with their intended materials and the specific technology it employs, such as CO2 or fiber lasers, to ensure it aligns with their cutting requirements.

Features and Applications

Equipped with advanced features, the laser cutting equipment is adept at delivering precise cuts for various applications. From intricate designs in the educational sector to robust tasks in industrial settings, these machines are capable of handling diverse challenges. The adaptability of the laser cutting system makes it a valuable asset in fields requiring precision and material conservation.

Material Compatibility and Advantages

The laser cutting machine 1626 is not limited to a single material type. Its robust build allows for the processing of leather, carbon steel, and even stainless steel, among others. The advantage of such a machine lies in its ability to maintain material integrity while ensuring minimal wastage, a critical consideration for cost-effective operations.

Choosing the Right Machine

Selecting the appropriate 1626 laser cutting machine involves assessing the work station's safety, understanding the material specifications, and the technology's compatibility with the intended cutting tasks. Prospective users should thoroughly evaluate these factors to find a machine that aligns with their operational needs and material handling requirements.

Operational Efficiency and Precision

The laser cutter 1626 is synonymous with operational efficiency, offering high-precision cutting capabilities. Its diverse features, such as varying power ratings and cutting heads, contribute to its performance, ensuring that each cut is executed with the utmost accuracy, which is essential for both intricate designs and bulk material processing.