Understanding Abrasive Cutting Machines

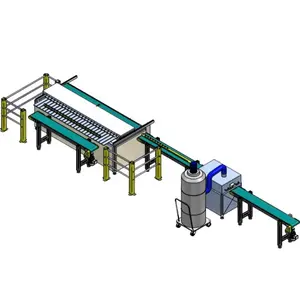

Abrasive cutting machines are essential tools in various industries, designed to slice through materials with precision and efficiency. These machines utilize abrasive wheels or abrasive water jet cutting technology to tackle the toughest cutting jobs. The category encompasses a range of equipment, from abrasive cutoff machines to specialized abrasive water jet cutting machines, each serving a unique purpose in material processing.

Types and Applications

The versatility of abrasive cutting extends to different types, such as the abrasive disc cutting machine and the abrasive wheel cutting machine. These variants cater to diverse applications, from slicing metals to precision cutting of delicate materials. Industries from automotive to aerospace rely on these machines for their ability to cut without thermal distortion, ensuring the integrity of the material.

Features and Materials

An abrasive cutting machine is engineered for performance and durability. The machines are compatible with various abrasives, including machining aluminum oxide and other materials used for water jet cutting abrasive materials. This adaptability allows for cutting a wide array of materials with precision, from metals to composites, without compromising on speed or quality.

Advantages of Modern Abrasive Cutting

Modern abrasive cutting equipment offers numerous advantages. Efficiency is at the forefront, with machines like the automatic abrasive cutting machine reducing labor and enhancing production speed. The precision of an abrasive jet cutting machine ensures minimal material waste, while the lack of heat-affected zones during cutting preserves the material properties.

Choosing the Right Machine

Selecting the right abrasive cutting machine involves considering several factors. The size of the machine should align with the workspace, while the power output should match the required cutting speed and efficiency. For instance, the Milwaukee 14 abrasive cut off machine is known for its balance between power and size, making it a popular choice for various industrial tasks.

Maintenance and Safety

While Alibaba.com offers a platform to connect buyers with a myriad of suppliers, it's crucial to consider maintenance and safety features. Machines like the Milwaukee heavy duty 14 abrasive cut off machine are designed with user safety in mind, incorporating guards and emergency stops. Regular maintenance, such as replacing Milwaukee 14 abrasive cut off machine parts, ensures longevity and consistent performance.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4