Popular in your industry

Top categories

About piezoelectric material

What is High-performance Piezoelectric Material

High-performance piezoelectric materials are advanced materials that exhibit strong piezoelectric properties, making them ideal for various applications ranging from sensors and actuators to energy harvesting devices. These materials are engineered to convert mechanical stress or pressure into an electrical charge, and vice versa, under specific conditions. The term high-performance denotes a superior ability to convert energy with minimal loss, which is a crucial aspect in the design of efficient piezoelectric systems.

Piezoelectricity is a phenomenon discovered by the brothers Jacques and Pierre Curie in the late 19th century. It is the property of certain crystals, ceramics, and polymers to generate an electrical charge when subjected to mechanical stress. The materials commonly used for high-performance piezoelectric applications include lead zirconate titanate (Pzt), which is a type of ferroelectric material, and its solid solutions. These materials can produce a high voltage and are highly responsive to changes in pressure or deformation, making them valuable for precise control in various fields such as sonar systems, medical devices, and wearable technology.

At the core of piezoelectric materials' functionality is the arrangement of their molecular structure. When a force is applied to these materials, the internal charge distribution shifts, resulting in an electric field. This electric field causes the material to deform slightly, a concept known as the piezoelectric effect. Engineers and designers can utilize this effect to create materials that are not only high-performance but also reliable over time.

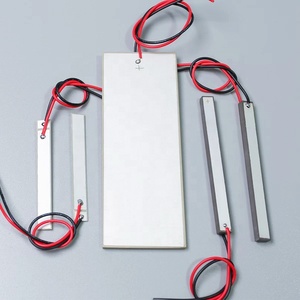

Types of High-performance Piezoelectric Materials

The field of high-performance piezoelectric materials is diverse, with various types serving distinct purposes and finding use in multiple industries. Here’s a closer look at some of these materials:

-

Piezoelectric Ceramics: These are robust materials used in applications requiring durability and resistance to harsh environments. They are commonly found in devices like ultrasonic transducers and high-power sonar systems.

-

Piezoelectric Polymers: Lightweight and flexible, these materials are ideal for applications involving wearables and smart sensors. Their adaptability makes them suitable for shape-conforming designs.

-

Single Crystal Piezoelectric Materials: Known for their high piezoelectric charge density, these materials are used in precision applications such as medical imaging and high-tech manufacturing.

-

Lead Zirconate Titanate (PZT)-Based Ceramics: These ceramics offer a combination of high piezoelectric performance and thermal stability. They are often employed in advanced medical devices and in cutting-edge manufacturing equipment.

Each type serves specific purposes depending on its inherent properties and the demands of its intended application.

How to choose High-performance Piezoelectric Material

Choosing the right high-performance piezoelectric material requires careful consideration of several factors. Understanding the application's specific requirements is critical; factors such as operating temperature range, frequency response, and the ability to generate high voltages should guide your choice.

For applications involving ultrasonic transducers or sensors, materials with high electromechanical coupling coefficients such as PZT or PMN-PT may be most suitable. These materials can efficiently convert electrical energy into mechanical vibrations or detect the resulting sound waves. When it comes to harvesting energy from ambient vibrations or using piezo crystals in wireless headphones, lead zirconate may be a better option due to its high piezoelectric coefficients.

Moreover, considerations must be given to the durability and performance consistency of these materials under various stress conditions. For example, PZT materials are known for their robustness and long-term stability, making them suitable for applications requiring materials with high resilience.

Lastly, businesses should take note of supplier capabilities on Alibaba.com to ensure they can procure materials that meet their quality standards and performance needs.

About High-performance Piezoelectric Material on Alibaba.com

Alibaba.com stands out as an ideal sourcing platform for businesses seeking high-performance piezoelectric materials. With an extensive network of suppliers offering a wide array of materials, businesses can find exactly what they need to meet their specific application requirements. Alibaba.com simplifies the procurement process by providing powerful search capabilities that help buyers locate materials based on attributes such as composition, voltage range, and more.

For businesses looking to scale their operations globally, Alibaba.com offers a Trade Assurance service that adds a layer of security by protecting payments until delivery is confirmed. This service exemplifies Alibaba.com's commitment to fostering trust within its B2B marketplace.

Moreover, Alibaba.com's user-friendly mobile platform supports multilingual communication and simplifies international trade. Whether you're sourcing piezoelectric ceramics from a supplier in South Korea or high-performance plastics from a vendor in Germany, Alibaba.com streamlines the process of connecting businesses with the materials they need to succeed in today's competitive market.

Common FAQs for High-performance Piezoelectric Material

What are piezoelectric materials used for in industry?

Piezoelectric materials are used in a variety of industrial applications, including as sensors for measuring vibration and pressure, as actuators for precise positioning and force generation, and as energy harvesters that convert mechanical stress into electrical energy.

How do piezoelectric materials work?

Piezoelectric materials generate electrical energy in response to mechanical stress. When a force is applied to the material, it causes the crystal lattice to deform, which results in a redistribution of the charge. This charge separation across the crystal leads to an electric field within the crystal that can be harvested for its electrical properties.

Can piezoelectric materials be integrated into existing electronic devices?

Yes, piezoelectric materials can be integrated into existing electronic devices for enhanced functionality. They are typically designed to be miniaturized and shaped to fit the required space and operational needs.

Are there different types of piezoelectric materials available?

There are several types of piezoelectric materials, each with specific properties that make them suitable for different applications. These can include ceramic elements, polymer films, and composite materials.

What should be considered when selecting a piezoelectric material for a specific application?

When selecting a piezoelectric material, consider the mechanical stress conditions it will be exposed to, its sensitivity and response time, environmental factors, and the required durability of the device.

How sensitive are piezoelectric materials to temperature and humidity?

Piezoelectric materials generally have good environmental tolerance, but their sensitivity can vary. Ceramic materials are known for their stable performance across a range of temperatures and humidities, while polymer films may have different characteristics.

Can piezoelectric materials be customized for specific applications?

Many suppliers on Alibaba.com offer customization options for piezoelectric materials, including varying dimensions, electrode configurations, and sensitivity levels to meet particular application requirements.

What is the typical lifespan of a piezoelectric material-based device?

The lifespan of a piezoelectric material-based device depends on the application and usage conditions. Some materials are more durable than others, but with proper care and maintenance, high-quality materials can last for several years.

How do I ensure I am purchasing high-quality piezoelectric materials?

When purchasing piezoelectric materials, look for suppliers that provide detailed product specifications and have positive ratings and reviews on Alibaba.com. Additionally, consider utilizing services like Trade Assurance to protect your order quality and delivery satisfaction.

Are there any environmentally friendly options for piezoelectric materials?

While the term environmentally friendly can be subjective, some piezoelectric materials are formulated with non-toxic components or are recyclable. Check product listings or inquire directly with suppliers about their material's environmental impact.

What factors impact the performance of a piezoelectric material in a vibration environment?

When exposed to vibration, some piezoelectric materials may generate electrical noise or become less sensitive. For optimal performance in dynamic environments, choose materials with a high damping coefficient or those that have been tested for vibration.

How is the stability of a piezoelectric material affected by temperature?

The stability of a piezoelectric material can be influenced by temperature variations. It is important to select a material with a high thermal stability if your application involves exposure to different temperatures.

Can piezoelectric materials be used in medical devices?

Piezoelectric materials are commonly used in medical devices due to their ability to provide precise control and sensitivity. However, they must meet specific biocompatibility and performance standards to ensure safe and reliable operation within the human body.

Is it possible to order small quantities of piezoelectric materials for prototyping purposes?

While Alibaba.com caters primarily to B2B bulk orders, some suppliers may accommodate small quantities for prototyping or sampling purposes. This is subject to individual supplier policies.

How do I find information about the toxicity levels of piezoelectric materials?

To find information about toxicity levels, you can review supplier-provided material safety data sheets (MSDS) or industry reports on specific materials. It is also recommended to inquire directly with suppliers about their product's toxicity levels.

Can I get assistance with choosing the right piezoelectric material for my application?

Many suppliers offer technical support and guidance in selecting the appropriate piezoelectric material based on your application's performance requirements. It is advisable to communicate directly with suppliers through Alibaba.com to get the best assistance.