What is Industrial Yarn Winding Machine

Industrial yarn winding machines are specialized equipment designed to wind yarn, a continuous length of interlocked fibers, into a form that is more easily managed, transported, and utilized in various industrial processes. These machines are an essential component in the textile industry, where they serve the crucial function of transforming raw, loose fibers into organized and ready-to-use yarn packages. The winding process ensures that the yarn can be further processed or directly sold to customers, enabling the functionality of the textile supply chain.

The users of these machines span a wide range of businesses, from small-scale garment manufacturers to large multinational textile factories. These machines are also vital for companies that produce sewing threads, as well as for those involved in the production of other types of yarns used in weaving, knitting, and embroidery. The efficiency and precision of these machines are key to both the quality of the yarn and the productivity of the overall operation.

The principle behind industrial yarn winding machines is relatively straightforward. They typically consist of a central spindle around which the winding takes place. The machine may have multiple spindles to wind several yarns simultaneously. The yarn is fed onto the machine at a constant tension to ensure uniformity in the winding process. The spindle's rotational speed and the tension control mechanism are critical for achieving the desired winding pattern and yarn characteristics.

Types of Industrial Yarn Winding Machine

The market offers a spectrum of industrial yarn winding machines, each tailored to specific applications and yarn characteristics. Here's a closer look at some of these varieties:

-

Manual Yarn Winding Machine: These machines require an operator to guide the yarn onto the package. They are typically used in smaller operations where the volume of production doesn't justify a more significant investment in automated machinery.

-

Automatic Yarn Winding Machine: Equipped with electronic sensors and programmable controllers, these machines handle larger volumes and more complex winding patterns without constant supervision. They're ideal for high-speed production lines where efficiency is paramount.

-

Mechanical Yarn Winding Machine: Offering reliability with fewer electronic components, mechanical yarn winding machines are suited for environments where precision and durability are key factors.

-

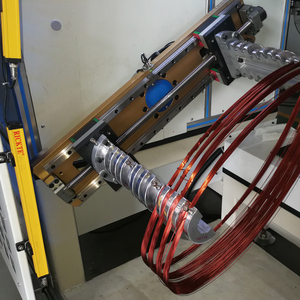

Hydraulic Yarn Winding Machine: With robust construction for heavy-duty use, hydraulic yarn winding machines can manage the tension required for winding industrial-grade yarns such as aramids.

-

Electric Yarn Winding Machine: These modern machines utilize electric motors and computerized controls to provide consistent tension and speed control, resulting in uniform packages of yarn.

How to choose Industrial Yarn Winding Machine

Selecting the right industrial yarn winding machine requires careful consideration of several factors:

-

Machine Compatibility: The chosen machine should be compatible with the other equipment in the production line. It should be able to handle the type and volume of yarn being wound, and the resulting package should meet the specific requirements of the subsequent processes.

-

Yarn Properties: Depending on the intended use of the yarn, different properties may be important such as tensile strength, elasticity, or heat resistance. The machine must be capable of preserving these properties while winding the yarn.

-

Automation Level: The degree of automation needed will depend on the volume of production and labor costs. A fully automatic machine may be necessary for high-volume environments where minimizing labor costs is a priority.

-

Technical Support and After-Sales Service: It's essential to choose a supplier who can provide adequate technical support and after-sales services like video support or field maintenance services.

-

Core Components Quality: Ensure that core components such as motors, gears, PLCs (Programmable Logic Controllers), and bearings are of high quality to guarantee reliable operation and reduce downtime.

By taking these factors into account when choosing an industrial yarn winding machine, businesses can make informed decisions that cater to their specific industrial needs.

About Industrial Yarn Winding Machine on Alibaba.com

Alibaba.com stands as a global marketplace connecting buyers with suppliers offering a wide range of industrial yarn winding machines suited for various applications. With an extensive selection from numerous suppliers around the world, Alibaba.com simplifies the procurement process for businesses looking to scale their operations or streamline their production processes. The platform's variety ensures that whether you're in textile manufacturing or other industries requiring yarn winding solutions—such as those used in metalworking or plastic production—there's a suitable machine available.

The website's user-friendly interface allows buyers to communicate effectively with suppliers in their local language and manage orders efficiently on mobile devices. With features like Trade Assurance that protect payments until delivery completion, Alibaba.com prioritizes secure transactions giving buyers confidence in their purchases.

By choosing Alibaba.com for your industrial yarn winding needs, you're not only accessing one of the most comprehensive selections in the market but also benefiting from a service tailored to international trade. This ensures that regardless of your location or size of your business, you have access to the right equipment that meets your operational requirements while fostering global business opportunities.

Common FAQs for Industrial Yarn Winding Machine

What are the key factors to consider when selecting an industrial yarn winding machine?

When choosing an industrial yarn winding machine, consider factors such as the variety of yarns being wound, machine compatibility, production volume, ease of operation, and the specific needs of your end-use market.

How does the choice of motor affect the performance of an industrial yarn winding machine?

The motor type can significantly impact the machine's performance. For instance, servo motors offer precise control and are ideal for high-speed winding, while stepper motors may be more cost-effective but less accurate.

What are the advantages of using a semi-automatic yarn winding machine?

Semi-automatic machines provide a balance between manual and fully automatic operation. They are typically faster than manual winding and can handle a higher volume of work with less strain on the operator.

Can industrial yarn winding machines handle different types of yarns?

Yes, most industrial yarn winding machines are designed to handle a variety of yarns including cotton, synthetic, wool, and specialty fibers. However, it is important to check the specifications of each machine to ensure it meets your yarn type.

What kind of after-sales support is available for industrial yarn winding machines?

After-sales support options vary by supplier but may include video technical support, online support, and field maintenance and repair services. Availability of these services should be confirmed with the supplier before purchase.

Are there specific industrial yarn winding machines for larger or smaller production volumes?

Yes, there are machines designed for both high-volume production as well as smaller operations. It's important to assess your production scale and choose a machine that aligns with your capacity needs.

What should I look for in terms of material construction for an industrial yarn winding machine?

Look for machines made from robust materials such as steel or cast iron that can withstand continuous use in an industrial environment. The quality of core components like motors and gearboxes is also crucial.

How does machine compatibility affect my choice in industrial yarn winding machines?

Machine compatibility is essential to ensure seamless integration with existing production equipment. Check the specifications provided by the supplier to ensure that the machine can be easily integrated into your operations.

What kind of maintenance is required for an industrial yarn winding machine?

Regular maintenance typically includes cleaning, lubricating moving parts, checking tension settings, and ensuring the machine is properly aligned and serviced according to the manufacturer's guidelines.

Can I find a supplier that offers an industrial yarn winding machine suitable for my business's local service location?

Many suppliers on Alibaba.com offer machinery suitable for various local service locations such as Vietnam, Egypt, Canada, India, Bangladesh, and Indonesia. Always confirm the supplier's ability to deliver to your location before making a purchase.

Is it possible to customize an industrial yarn winding machine according to my business's specific requirements?

Customization options vary among suppliers. It's advisable to discuss your specific needs directly with suppliers to understand their capacity for customization and any associated costs.

How do I determine the right machine size for my business's needs?

Consider your production volume and the specific requirements of your product range. Suppliers can provide guidance on the appropriate machine size based on your operational scale.

Are there environmentally friendly options available in industrial yarn winding machines?

Yes, some suppliers offer energy-efficient or eco-friendly machines. Look for features like energy-saving motors or those specified as being eco-friendly in the product descriptions.

What types of yarn windings can be handled by an industrial yarn winding machine?

Industrial yarn winding machines can handle a wide range of yarn windings including cone winding, hank winding, parallel winding, and cross-wound spools.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4