Popular in your industry

Top categories

About cold rolled steel sheet prices

A Guide to Cold Rolled Steel Sheet Prices

A byproduct of the cold rolling technique, cold rolled steel sheet is a flat steel product utilized across various sectors such as automotive, construction, and manufacturing. The essence of cold rolling lies in its ability to produce a thinner, more precise steel sheet than the hot rolling method. This is achieved by passing the steel through rollers at ambient temperature, thus altering its thickness and enhancing its grain structure.

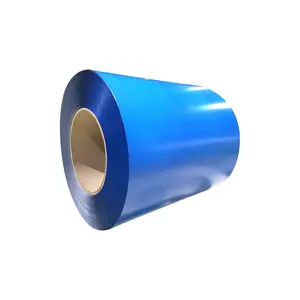

The importance of cold rolling cannot be overstated when it comes to fabricating steel sheets that adhere to exacting dimensional tolerances and possess the requisite surface finish for their intended applications. The end product is typically stronger and more resilient than its hot rolled counterpart, making it ideal for uses demanding high structural integrity and dependability. Additionally, cold rolling can endow steel sheets with various surface treatments, such as color coatings, prepainting, and metallic coatings like zinc, which improve their resistance to corrosion and visual appeal.

Industries ranging from construction and manufacturing to automotive production depend on the adaptability and superior quality of cold rolled steel sheets. Their ease of formability and robustness are indispensable for creating products that must endure considerable stress and strain. Cold rolled steel sheets are also a staple in the fabrication of appliances, electronics, and within the industrial realm.

Assessing Cold Rolled Steel Sheet Prices

On Alibaba.com, cold rolled steel sheet prices are differentiated based on factors such as type, grade, thickness, and intended use. Below is a synopsis of prevalent varieties:

-

Carbon Steel Sheets: These represent the most economical variety of cold-rolled steel sheets. Renowned for their strength and adaptability, they are frequently employed in construction and automotive part manufacturing.

-

Alloy Steel Sheets: Infused with additional metals to bolster their strength and resistance to corrosion, alloy steel sheets are typically utilized in niche markets like aerospace and energy.

-

Stainless Steel Sheets: Known for their exceptional resistance to corrosion, these sheets are optimal for environments where cleanliness is crucial, such as in food processing facilities and marine settings.

-

Galvanized Steel Sheets: Coated with zinc for added protection, galvanized steel sheets are a popular choice for construction projects that are exposed to the elements.

-

Color Coated Steel Sheets: These sheets are finished with a layer of color, tailored for aesthetic purposes in architectural applications like cladding and roofing where color is a key consideration.

Selecting Cold Rolled Steel Sheets: A Pricing Guide

In choosing cold-rolled steel sheets for commercial use, several factors must be weighed:

-

Grade and Application: The steel's grade should match its intended use. While carbon steel sheets are versatile and fit for a broad range of applications, specific industries may necessitate specialized grades such as 304 or 316 stainless steel.

-

Surface Finish: The desired end product dictates the importance of the steel sheet's surface finish. Certain applications, like specific printing processes, may require a smooth finish, whereas a matte finish might be preferable for items that will undergo painting or powder coating.

-

Processing Services: Additional services such as bending, welding, or punching may be necessary and are provided by suppliers. It is essential to select a steel sheet that maintains its structural integrity even after such manipulations.

-

Quality Certifications: Seek out quality certifications like ASTM or JIS to ensure the materials conform to industry-specific standards.

-

Supplier Reliability: Sourcing from credible suppliers who consistently deliver quality products is vital. Alibaba.com enables businesses to evaluate supplier reliability through user ratings and reviews.

Understanding Cold Rolled Steel Sheet Prices on Alibaba.com

Alibaba.com distinguishes itself as a comprehensive marketplace that streamlines global trade by connecting businesses with trustworthy suppliers of a wide array of cold rolled steel sheets. With over twenty years of experience in B2B transactions across diverse industries, Alibaba.com has become a dependable platform for sourcing materials with assurance.

Customers in search of cold rolled steel sheets will appreciate the extensive selection on Alibaba.com. The platform's user-friendly interface permits buyers to sort products by specific criteria such as ASTM or DIN standards, processing services like bending or welding, grade specifications including Q195 or DX51D, and surface treatments such as color coating or zinc plating. This degree of customization guarantees that companies can find products that are precisely aligned with their project requirements, all while enjoying competitive wholesale prices.

Furthermore, Alibaba.com's dedication to transaction security through offerings like Trade Assurance adds an extra measure of confidence to purchases. The platform's international scope ensures that businesses, regardless of location, have access to a diverse supplier base and products that can support their production objectives. Whether the need is for a modest quantity for local construction or substantial orders for industrial machinery components, Alibaba.com is adept at facilitating your procurement process efficiently, maintaining high-quality standards across all product categories.

Frequently Asked Questions About Cold Rolled Steel Sheet Prices

What distinguishes cold-rolled from hot-rolled steel sheets?

Cold-rolled steel sheets are fashioned at room temperature and boast a smooth, matte finish, making them well-suited for applications that demand a refined finish, such as automotive components, office furniture, and appliances. Conversely, hot-rolled steel sheets are produced at elevated temperatures and are generally employed in the creation of rails, structural beams, and various metal products due to their coarser surface texture.

How does surface treatment influence the selection of cold-rolled versus hot-rolled steel?

Surface treatment plays a significant role in the corrosion resistance, aesthetic quality, and application suitability of both cold and hot-rolled steel sheets. Sheets that are pre-painted or color-coated provide extra protection against rust and scratches, making them suitable for external or visible uses.

Why is material grade important in cold-rolled steel sheets?

The material grade signifies the steel's quality and robustness. Higher grades typically offer enhanced performance and are ideal for demanding uses in sectors like construction or automotive, where longevity is key.

Is it possible to tailor cold-rolled steel sheets for particular uses?

Indeed, cold-rolled steel sheets can be customized in dimensions, thickness, and with additional processes such as bending, welding, punching, and decoiling to meet the unique demands of various applications.

What are common uses for cold-rolled steel sheets?

Cold-rolled steel sheets are frequently employed in the automotive industry for fabricating lightweight panels and brackets, as well as in construction for roofing, walls, and other structural elements.

How does Alibaba.com guarantee the quality of cold-rolled steel sheets on its platform?

Alibaba.com connects buyers with global suppliers and ensures transaction security with services like Trade Assurance, which upholds the quality and reliability of the products purchased.

Are there standards that regulate the quality of cold-rolled steel sheets?

Certainly, industry standards such as ASTM, JIS, GB, and DIN set forth specific criteria for cold-rolled steel sheets, covering aspects like chemical composition, mechanical properties, and production methods.

What processing services are applicable to cold-rolled steel sheets?

Common processing services like bending, welding, punching, decoiling, and skin pass are applied to cold-rolled steel sheets to enhance their shape and functionality for a range of applications.

In what ways does surface treatment affect the performance of a cold-rolled steel sheet?

Surface treatments such as cold-rolled (CR) or pre-painted coatings provide additional defense against corrosion and wear, making them more suitable for challenging environments or applications.

What considerations should guide the choice of thickness for a cold-rolled steel sheet?

The selection of a cold-rolled steel sheet's thickness should be informed by the structural demands of the application, with thicker sheets providing more strength and rigidity, while thinner sheets may be preferred for decorative purposes or when weight is a factor.

Are cold-rolled steel sheets appropriate for marine environments?

Certain cold-rolled steel sheet variants are specifically designed for marine settings, with coatings or treatments that offer enhanced resistance to saltwater corrosion.

Is it feasible to source eco-friendly cold-rolled steel sheets?

Yes, eco-friendly options for cold-rolled steel sheets are available, focusing on sustainable materials and processes. Suppliers may provide recyclable products or those with a reduced environmental footprint.