Over 20 Years SPCC Brass Metal Aluminium Mould Iron Custom Sheet Metal Stamping Tools Manufacturer High Precision Motul Product

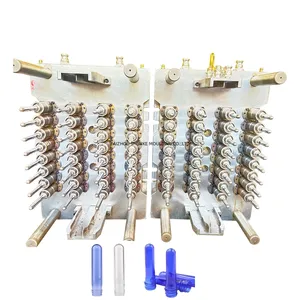

Manufacturer Precision Custom Small Parts Maker Transparent Water Bottle Mould Plastic Injection Mold

Bottle moulds are pivotal in the production of a wide array of bottles used across various industries. These moulds are the essential templates from which bottles for beverages, pharmaceuticals, personal care products, and other commercial goods are created. The process involves shaping materials such as PET, glass, or plastic into a functional and aesthetically pleasing product. The versatility of bottle mould designs allows for a vast range of sizes, shapes, and functionalities, catering to the specific needs of businesses.

The application of bottle moulds spans several industries, each requiring distinct specifications. PET bottle mould and plastic bottle mould are commonly used for consumable products due to their lightweight and durable nature. In contrast, glass bottle mould is preferred for premium beverages and products where quality perception is critical. Specialized moulds like the wine bottle cake mold and bottle opener resin mold cater to niche markets, offering unique shapes and designs for confectionery and crafting purposes.

The materials used in bottle mould manufacturing are chosen for their durability and resilience. Iron and aluminum are frequently utilized for their longevity and ability to withstand the high pressures of bottle blow molding and injection molding bottles. Silicone variants, such as bottle silicone mould and silicone bottle mould, offer flexibility and are often used for intricate designs and consumer products. The features of these moulds are designed to ensure precision, ease of use, and compatibility with different manufacturing processes, including blowmoulders and bottle injection molding.

Optimizing a bottle mould design can significantly reduce production costs and increase operational efficiency. Standardizing components like lift bars, connection sizes, and clamp slots can make the moulds more interchangeable and reduce downtime during the manufacturing process. This standardization is particularly beneficial for businesses that utilize multiple moulds for different products, such as those involved in bottle cap injection molding and PET jar mould production.

Selecting the appropriate bottle mould involves considering the intended use, material compatibility, and the specific manufacturing process. Whether it's for PET blow molding or crafting a unique bottle silicone mold, the design and material of the mould must align with the product requirements. Suppliers on Alibaba.com offer a range of options and can provide insights into the best practices for mould utilization, ensuring that buyers find the right mould for their production needs without the hassle of extensive trial and error.

In conclusion, the diverse range of bottle moulds available caters to a multitude of industry needs, from standard beverage containers to specialized product designs. By leveraging the variety and expertise available through Alibaba.com, businesses can find the moulds that meet their production demands and drive their products' success in the market.